Robotic Automation Solutions by Top Manufacturers

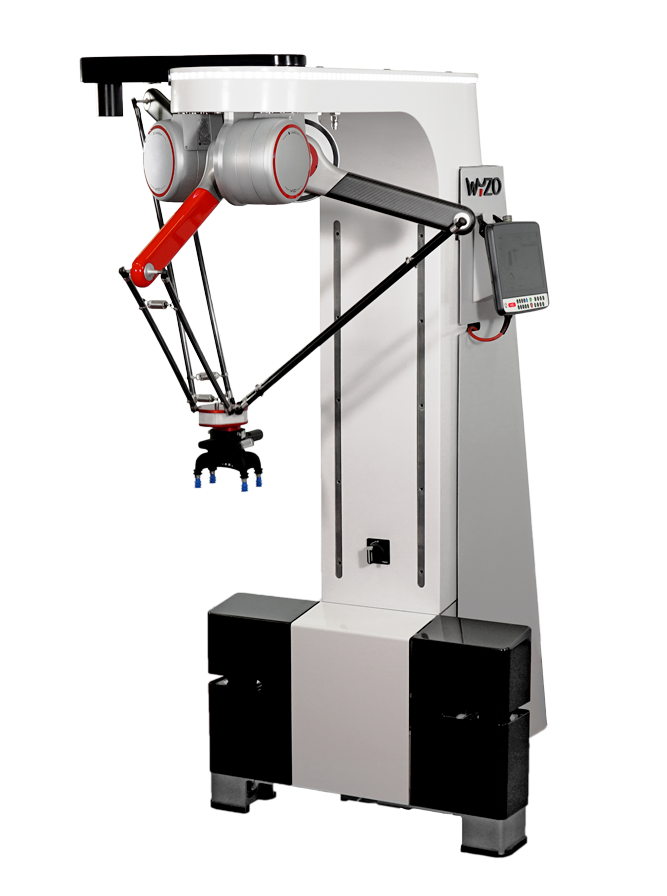

Robot Tooling & Accessories

Our diverse selection of grippers and tooling caters to a wide range of applications in both collaborative and industrial automation. Including advanced gripping technologies, sensors, and various tools for tasks like assembly and machine tending, these solutions enhance process optimization for manufacturers. They offer the flexibility and compatibility needed across different robot brands, ensuring an effective automation investment for businesses of all sizes, especially in enhancing productivity and quality.

Robots Usage is on the Rise

Robot installations have grown exponentially in recent years. Robots have been around in industry performing many tasks such as welding and material handling since the 1980s. The recent boom is a result of decreasing costs and ease of use. Emerging markets such as the area of collaborative robotics have stemmed further growth allowing robots to be used in many new applications.

Modern robots are easier to put into place than many would think. Robot manufacturers are streamlining integration and deployment, making it more accessible to companies who are new to robotics.

Common Use-Cases for Robotics

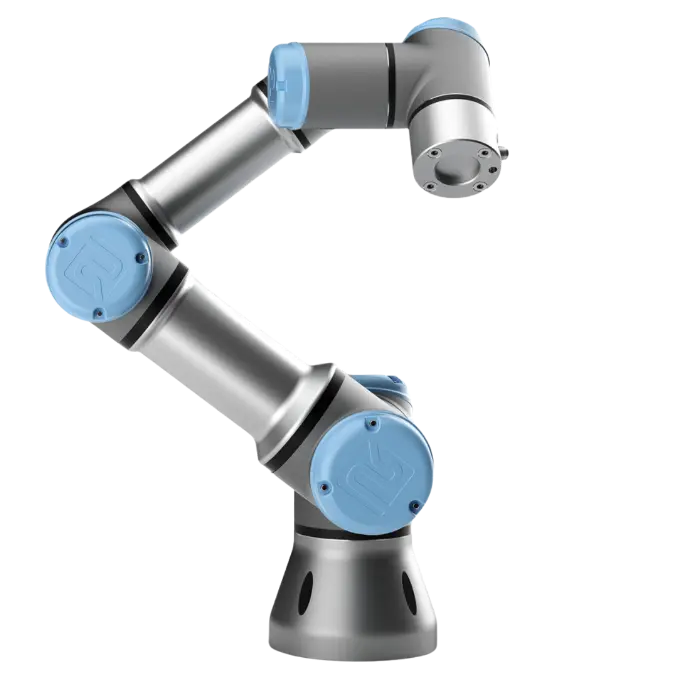

Our Robot Brands

What are the Benefits of Implementing Robotics into a Manufacturing Process?

Return on Investment

Leverage Robots to boost your productivity and and combat the shortage of manual labor. RIA (Robotics Industries Association) offers a free ROI Calculator to help estimate cost savings.

Gain Redeployable Assets

Robots can be easily retooled and repurposed should the need arise. Robots are great assets and retain their value.

Ease of Use

Robots are so much easier to use than you might expect. Many people can learn to teach and program robots with very little effort..

Save on Labor Costs

We've all heard about the labor issues. Flexible Automation allows for re-allocation of human labor from dangerous, repetitive tasks.

Skyrocket Efficiency

Reduce costs of your operations and keep your business running smoothly.

Increase Product Quality

Flexible automation of processes allows for standardized product, and lets you maintain control on your business's products.