Our Approach to Automating an Assembly Process

Our team takes an integrated and thoughtful approach when working on an assembly automation project. We develop a system with the best components available on the market to fit your budget.

This approach empowers our engineers to fine-tune the robotic assembly techniques, tooling selection, and assembly sequences to match the intricacies of the components being assembled. This level of adaptability optimizes efficiency and accuracy, resulting in increased productivity and minimized errors.

Automating an assembly process helps manufacturers:

- Eliminate ergonomic strain on employees performing monotonous, repetitive assembly tasks.

- Enhance quality control and consistency of assembled products.

- Speed up the assembly line, increasing throughput and capacity.

- Reduce overhead costs, contributing to a more profitable production line.

Assembly Automation Testing

In partnership with leading manufacturers, our team is able to run a test of how we would automate your assembly process at no risk to you. This includes building out a proof of concept as well as testing for throughput and repeatability.

Through this process, we can provide a clear line of sight into what your automated assembly process would look like in regards to feasibility, cycle time, tooling needs, and return on investment.

Featured Resource: Maximizing Integration Efficiency with Vibratory Feeding Solutions

Get in Touch with Our Team

Assembly Solutions from Leading Manufacturers

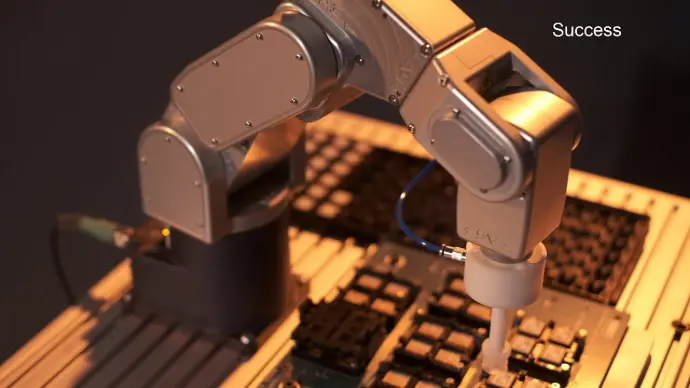

OnRobot Screwdriver

Automated screwdriving to boost productivity and quality has never been easier, smarter, or more cost-effective. Precise torque control and embedded axis eliminate the time and cost for additional integration and ensures consistent, accurate screw insertion. Changeovers to a different screw type or size take just minutes, reducing downtime and boosting ROI.

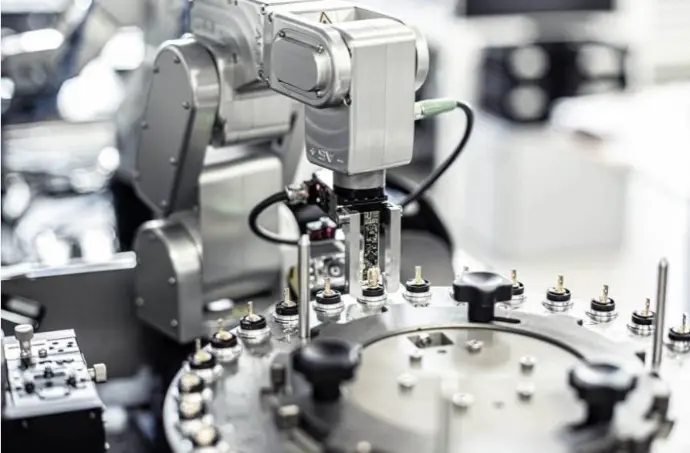

Meca500 Industrial Robot

The Meca500 is by far the smallest and most compact six-axis industrial robot arm. It is also the most precise one. And unlike most other industrial robots—which are usually complex stand-alone systems—the Meca500 is a plug-and-work automation component. This robot is a slave component rather than a master, which makes it very easy to integrate via any computer or PLC.

Asycube Vibratory Feeder

Asyril develops high performance flexible feeding systems for parts and components from 0.1 up to 150 mm in size. Their unique 3-axis vibration technology and intelligent vision system are easy to integrate and allow for optimized speed, accuracy and flexibility. The Asyril Asycube Series is compatible with all kinds of parts, and can perfectly handle complex geometries.