Industrial Automation Solutions

Our team of engineers have the ability to handle projects both big and small. We're able to handle every step in the process, from conceptual design all the way to the service and support for your new automations system.

We've been in the business for over 20 years, helping businesses of all sizes achieve optimal process improvement and ensure effective deployments for all sorts of applications. Leveraging industry experts in a wide range of industrial fields, we bring the experts directly to your project. We're happy to do as little or as much as you would like - whether that entails full design, setup, and ongoing support or anything in between. Our common focus areas are listed below, but we often take on "odd ball" projects as well. If you don't see something that you're looking for, send our team a message and we'll be in touch soon!

Motion Control Solutions

Our team specializes in a suite of services focused on motion control and motor selection. Our team's expertise extends as far as your project demands - after all, motion control is where BlueBay Automation started! We offer services including but not limited to:

- Motor Sizing and Selection

- Application Reviews & Assistance

- Motion Control Integration

- Part Sourcing & Crossover Services

- Custom Gearbox Manufacturing

At BlueBay, we're experts in motion control. We partner with the industry's leading manufacturers to provide you the best-of-breed solution. Below, you'll find a list of those manufacturers.

Collaborative and Industrial Robotics

Robots have been around in industry performing many tasks such as welding and material handling since before the 80s - and it's only gotten easier to deploy these solutions into your process. Businesses are seeing the following benefits when deploying robotic solutions into the proper process:

- Savings on Labor Costs

- Increasing Product Quality

- Increased Workforce Safety

- Increased Production Output

At BlueBay, we deploy industrial and collaborative robotics in a wide variety of applications. We partner with the industry's leading manufacturers to provide you the best-of-breed solution.

End of Arm Tooling

We carry robot grippers for both industrial and collaborative robots. These grippers are manufactured by industry leaders like OnRobot and Schunk, as well as custom designed in-house by our engineering team.

Some examples of applications that our grippers are able to handle:

- Pick and place

- Screwdriving and assembly

- Machine tending

- Palletizing

- Packaging

- No-mark gripping

- Food-grade gripping

- Sanding and material removal

- Magnetic gripping

- Force-adjusted gripping

GRIP Tool Changers

The GRIP Connector establishes connections swiftly, effortlessly, and intuitively. - providing nearly limitless options for linking cobots and tools.

GRIP's connection systems serve as the essential interface between robots and tools. Their quick-change systems consistently meet the rigorous standards of top-quality robot technology.

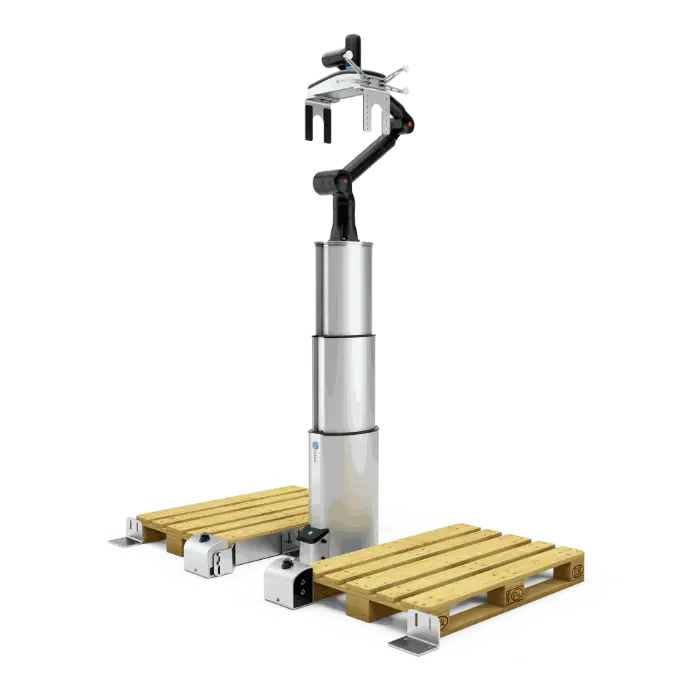

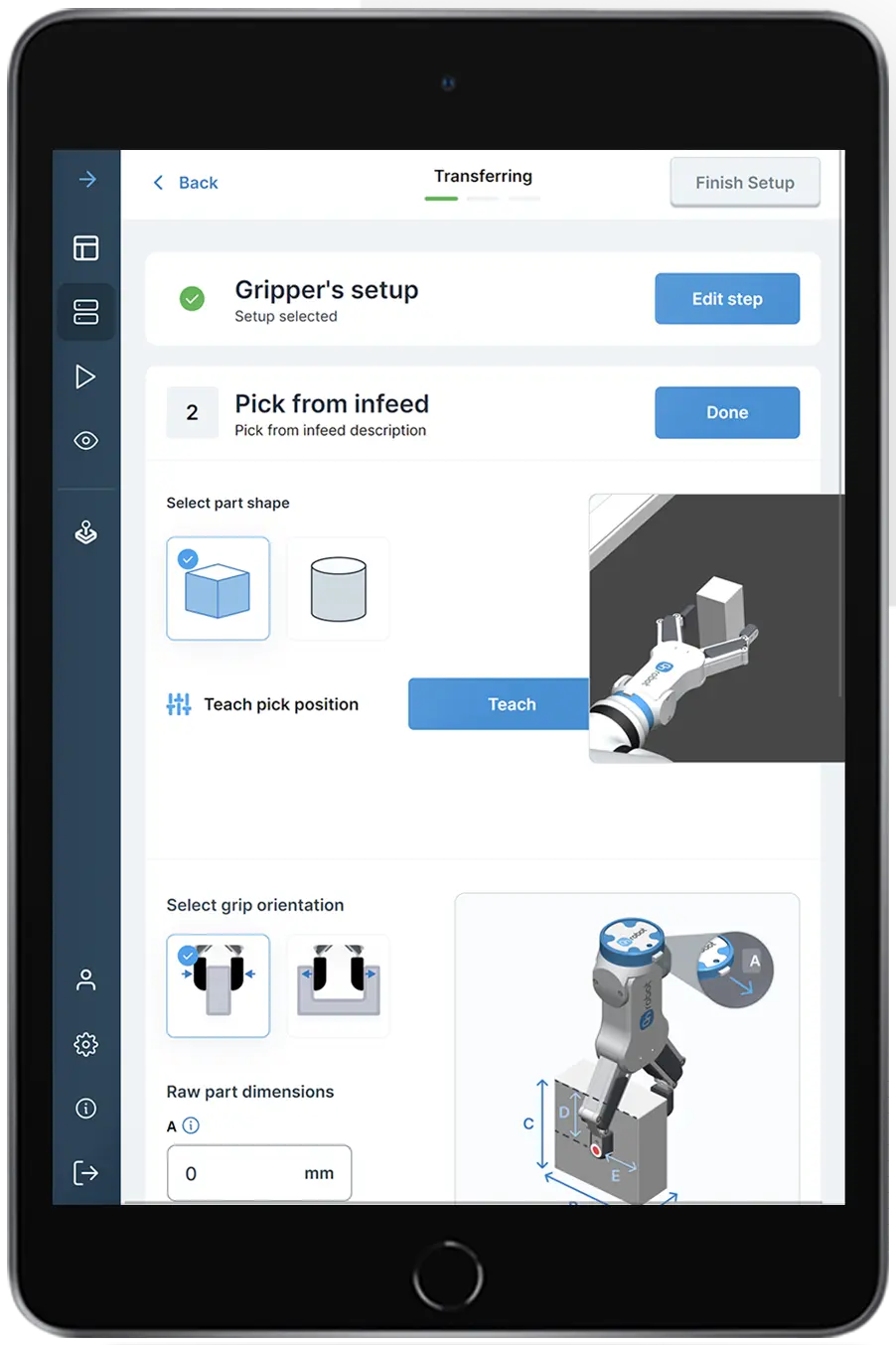

Meet D:PLOY from OnRobot

D:PLOY is industry’s first automated platform for building, running, monitoring, and re-deploying collaborative applications. It automates the process of getting a robotic application up and running, allowing deployment directly on the manufacturing floor, with zero programming and zero simulations. With D:PLOY, complete applications can be deployed in just a few hours.

The D:PLOY platform combines hardware and software to deliver solutions that address various robotic applications. Today, D:PLOY supports the following applications, with more to follow.

- Palletizing

- Transferring

- CNC Machine Tending

- Packaging

Collaborative and Industrial Robotics

Robots have been around in industry performing many tasks such as welding and material handling since before the 80s - and it's only gotten easier to deploy these solutions into your process. Businesses are seeing the following benefits when deploying robotic solutions into the proper process:

- Savings on Labor Costs

- Increasing Product Quality

- Increased Workforce Safety

- Increased Production Output

At BlueBay, we deploy industrial and collaborative robotics in a wide variety of applications. We partner with the industry's leading manufacturers to provide you the best-of-breed solution.

Sensing and Vision Solutions

We've partnered with top manufacturers to bring you best-of-breed vision solutions for your applications. With our dedicated and experienced team of engineers, we're able to help as much as you need for your next project requiring sensing or vision components.

Some examples of what we carry:

- Machine Vision

- Barcode Readers

- Auto ID Systems

- Standard Sensors

- AI Vision Systems

Vibratory Part Feeders

BlueBay Automation offers vibratory part feeders, an essential tool for automating the handling and orientation of parts in manufacturing processes. These feeders ensure a consistent and reliable supply of components, streamlining the assembly line.

Benefits to businesses include:

- Improved efficiency in the assembly process through consistent part delivery.

- Reduced labor costs by automating manual sorting and orienting tasks.

- Enhanced product quality and consistency by ensuring correct part orientation.

- Increased production speed, supporting higher throughput and productivity.

Marking and Engraving Tools

Our team has partnered with leaders in the laser marking and laser engraving space - allowing us to offer top-tier solutions for your applications. Here you will find stand-alone systems to be used with a variety of materials, or markers that can be integrated into new or existing systems. Products like:

- Laser Tables

- Laser Stations

- Engraving & Routing Solutions

- Dot Peen & Scribing

- Software

- Integration-Ready Solutions

Industrial Software

BlueBay Automation provides advanced industrial software solutions designed to optimize manufacturing processes and enhance operational efficiency. These software offerings integrate seamlessly with existing systems, providing real-time data analysis and automation capabilities.

Benefits to businesses include:

- Increased productivity through automation and efficient process management.

- Enhanced decision-making with real-time data and analytics.

- Reduced operational costs due to improved efficiency and error reduction.

- Greater flexibility and scalability to adapt to changing market demands.

Automation Controls & More

Our team partners with industry leading manufacturers which enable us to quickly provide our customers with best-of-breed automation components.

A few examples of the solutions that we carry:

- Electrical components

- Protection and signaling

- Encoders

- Terminal Blocks

- Gearboxes and servo systems

- Enclosures

- Safety devices

- Panel meters

- & more!

Leak Test Solutions

As a premier provider of advanced air leak test instruments and automated leak testing systems, LeakMaster collaborates with manufacturers to identify optimal leak detection solutions tailored to specific applications.

Some examples of industries and applications which these systems are applicable for are:

- Fuel delivery systems

- Exhaust systems

- Drive Train

- Medical Devices

- ATVs

Marking and Engraving Solutions

Our team has partnered with leaders in the laser marking and laser engraving space - allowing us to offer top-tier solutions for your applications. Here you will find stand-alone systems to be used with a variety of materials, or markers that can be integrated into new or existing systems. Products like:

- Laser Tables

- Laser Stations

- Engraving & Routing Solutions

- Dot Peen & Scribing

- Software

- Integration-Ready Solutions

Industrial HMIs

BlueBay Automation provides top of the line HMI (Human-Machine Interface) panels, enabling intuitive interaction between operators and machinery in industrial settings. These panels facilitate efficient control and monitoring of manufacturing processes, enhancing user experience and operational effectiveness.

Benefits include:

- Improved ease of use and efficiency through user-friendly interfaces.

- Enhanced monitoring and control of industrial processes.

- Reduced downtime with quick diagnosis and troubleshooting features.

- Increased productivity due to streamlined operator-machine interaction.

To be successful your content needs to be useful to your readers.

Start with the customer – find out what they want and give it to them.

Machine Tending Automation

Machine tending offers a fast path to ROI through optimized automation. By integrating specialized components tailored to your machine specifications and part requirements, we provide solutions that enhance productivity and reduce manual effort. Our team ensures a seamless, affordable integration, adapting the automation to fit right into your existing workflow.

Why Automate Machine Tending?

- Rapid ROI

- Customized Components

- Reduced Downtime

- Enhanced Worker Safety

- Consistent Quality Control

With our machine tending automation, you’ll experience a dependable, high-performing solution that scales with your production, providing long-term value and efficiency.

Bin Picking Automation

Our bin picking solutions offer unmatched flexibility and adaptability, enabling you to reschedule tasks, reposition the system, and handle a higher volume of work with minimal supervision. Automate complex pick-and-place operations safely and efficiently, reducing repetitive movements and minimizing contact with hazardous materials.

Key Advantages:

- Flexible Task Scheduling

- Easy Mobility

- Increased Task Volume

- Safe and Reliable Automation

- Reduces Repetitive Movements

- Handles Hazardous Materials Safely

Our solution brings dependable automation to bin picking, making it simpler to scale and manage even the most challenging tasks in your workflow.

Robot Dispensing

We offer advanced dispensing tooling for robots and pre-engineered dispensing cells that streamline material application across various industries.

Applications include:

- Adhesive Application: Precise bonding for assembly and component attachment.

- Sealant Dispensing: Effective sealing for leak prevention and product durability.

- Coating Processes: Consistent application for protective and aesthetic finishes.

- Lubrication Systems: Ensures smooth operation of machinery and parts.

Palletizing Automation

We offer pre-engineered robotic systems and end-of-arm tooling for palletizing projects of all sizes. Our turnkey solutions combine leading robotic arms, adaptable grippers, and fast setup options to streamline your production.

Some key benefits of automating a palletizing process include:

- Increased Throughput: Automate end-of-line stacking to accelerate production.

- Improved Safety: Reduce manual lifting and repetitive strain for workers.

- Consistent Quality: Achieve precise, uniform pallet loads every time.

Cobot Welding Cells

With an estimated welder shortage of over 400,000 welders being needed by 2025, automating your welding process is an excellent way to future-proof your business and ensure quality, consistent welds. Our cobot welding cells manufactured by our Spartan Robotics division contain top tier welding technology and provide ultimate flexibility - allowing your employees to get up to speed quickly and allowing your business to get product out the door faster.

- Custom-built cobot welding cells

- Added maneuverability with the extra axis

- Leading welding equipment

- Easy to use software and operator interface

Automated Material Removal

Automating the material removal process with robotic technology can yield a business the following benefits:

- Alleviate Physical Strain on Workers:

- Improve Quality and Consistency

- Increase Efficiency and Throughput

- Lower Overhead Costs

- Quick Deployment and Reliable Output

Our systems are designed for quick deployment and consistent output for your process

Automated Assembly Cells

Automating an assembly process with robotic technology can yield a business the following benefits:

- Eliminate ergonomic strain on employees performing monotonous, repetitive assembly tasks.

- Enhance quality control and consistency of assembled products.

- Speed up the assembly line, increasing throughput and capacity.

- Reduce overhead costs, contributing to a more profitable production line.

Our solutions are designed for quick deployment and consistent output for your process.

Packaging Automation

Our packaging automation solutions bring together pre-engineered robotic systems and custom end-of-arm tooling, designed to handle diverse packaging tasks with precision and speed. Featuring industry-leading robotic arms and specialized grippers, our systems integrate seamlessly to streamline your production line.

Why Automate Your Packaging Process?

- Faster Packaging Cycles: Achieve quick, efficient packing speeds to keep up with high demand.

- Reduced Manual Effort: Automated handling cuts down on repetitive manual tasks, enhancing worker safety.

- Enhanced Consistency: Maintain reliable, uniform packaging, reducing product variation and minimizing waste.

Our tailored packaging solutions adapt to your unique operational needs, ensuring a smooth, dependable process that scales with your business.

Lab Automation Solutions

We specialize in robots designed specifically for laboratory automation and offer fully customizable systems to fit unique lab needs. Our solutions streamline scientific and research workflows, bringing precision and efficiency to every task.

Key Advantages of Our Lab Automation Solutions:

- Enhanced Accuracy and Consistency

- Higher Throughput and Efficiency

- Reduced Human Error and Improved Safety

- Cost Savings Over Time

- Flexible and Scalable Designs

Our lab automation robots provide reliable, adaptable solutions that optimize productivity, safety, and cost-effectiveness in any lab setting.