Expertise in Packaging Automation

Our team has developed and deployed automation solutions across various industries. Areas of specialization include:

- Multi-Product Packaging: Combining multiple product types or variants into a single package, such as variety packs or sampler sets.

- System Optimization: Configuring existing packaging equipment to meet specific operational requirements.

- Scalable Automation: Designing systems for products of varying sizes, from small medical components to large industrial items, while addressing challenges like product changeovers or seasonal demand shifts.

Comprehensive Packaging System Components

BlueBay Automation provides cutting-edge components for advanced packaging systems. Our solutions integrate the latest motion control technologies and precision gearing systems to ensure reliability and adaptability in diverse packaging applications.

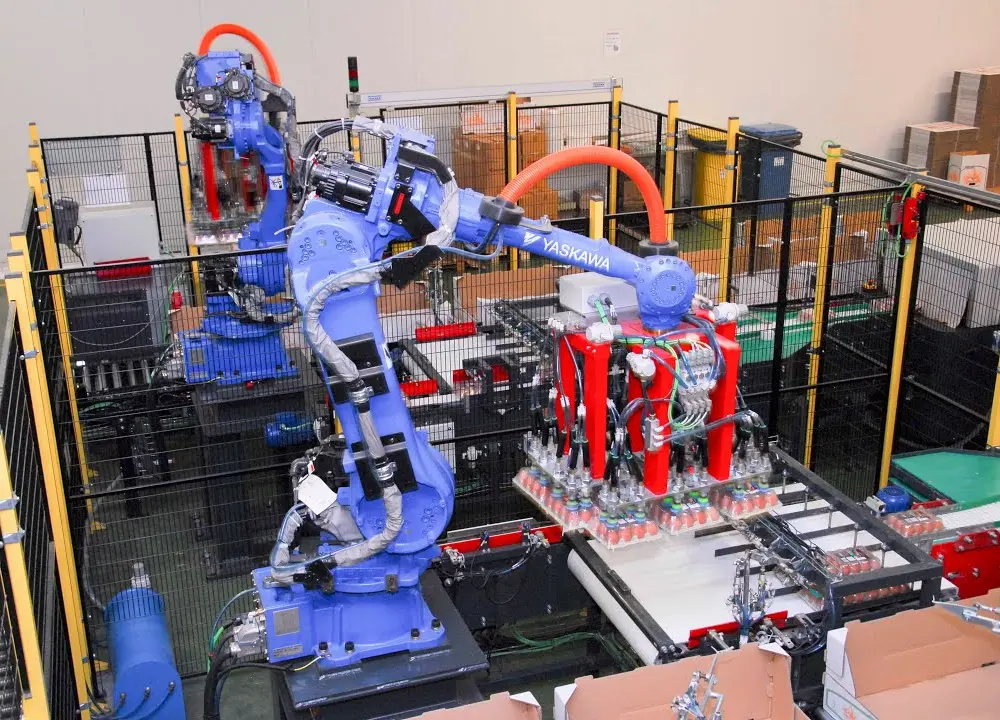

Yaskawa Motion Control and Drives

- Sigma-X Servo Series: Industry-leading performance for precise, efficient motion control.

- iCube Controller: Fully integrated automation and safety platform for streamlined operations.

- GA500 and GA800 AC Drives: Flexible and reliable solutions for variable speed control in demanding applications.

Key Benefits

- Expert sizing and application reviews by certified Yaskawa specialists.

- Early access to Sigma-X and iCube technologies.

- Competitive pricing and an extra year of warranty with our drive startup service.

BlueBay Automation delivers Yaskawa solutions backed by award-winning reliability and global certifications, ensuring your system is built to last.

Custom and Standard Gearing Solutions

- Leading Manufacturers: Tandler, Watt, Sesame, Wittenstein, and ZIMM screw jack systems for linear motion.

- Custom Gearbox Modifications: High-speed, shock-resistant designs, special ratios, and unique environmental configurations.

Customization Options

- Dimension modifications and special mounting requirements.

- High-temperature, washdown, or other extreme condition designs.

- Unique materials, lubrication, or paint for specialized needs.

When standard products fall short, our engineers collaborate to develop tailored solutions that deliver high performance without excessive costs or delays.

Simplify Packaging Automation with D:PLOY

Our packaging automation systems are powered by D:PLOY, a platform designed to deploy robotic packaging applications quickly and efficiently. With D:PLOY, you can set up and operate a complete packaging system in just a few simple steps, achieving deployment time savings of at least 80%.

Key benefits of D:PLOY Packaging include:

- Fast and Easy Deployment: Get your system up and running in hours with zero programming or simulations.

- Adaptable and Flexible: Easily redeploy for new products, container sizes, and packaging patterns.

- Enhanced Productivity: Eliminate downtime and boost throughput while reducing repetitive, injury-prone tasks for employees.

D:PLOY works seamlessly with leading collaborative and light industrial robot arms and features an intuitive interface for quick setup and monitoring. From initial cell setup to real-time operation, our systems deliver simplicity without sacrificing performance.

Packaging Automation for Every Stage

We design automation solutions for all levels of packaging, tailored to operational requirements:

Primary Packaging

Automates initial product feeding and packaging to reduce manual interaction and improve precision. Solutions include vibratory feeders, hoppers, and robotic systems to handle products before packaging them into containers.

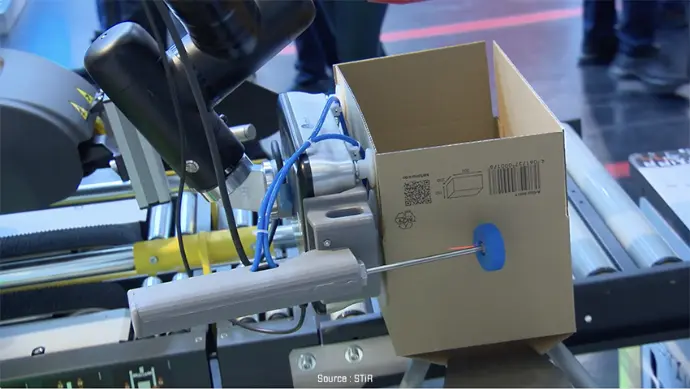

Secondary Packaging

Streamlines processes for protecting products during transit or improving presentation for retailers. Automated solutions ensure consistency in wrapping, bundling, and labeling while optimizing space and efficiency.

Tertiary Packaging

Incorporates robotic palletizing and wrapping systems for bulk packaging, reducing manual handling and enabling faster, safer, and more reliable operations. Systems are reconfigurable for changing product specifications.

Evaluation and Implementation

BlueBay Automation provides comprehensive assessments of your packaging operations to identify automation opportunities. Our team delivers feasibility studies, proof-of-concept demonstrations, and detailed ROI analyses to ensure that each solution is aligned with your specific needs.

Start Optimizing Your Packaging Processes

Contact BlueBay Automation to learn how our engineering expertise and leading technologies can transform your packaging operations. Our team is ready to assist with designing and implementing systems that deliver measurable improvements in efficiency, safety, and cost savings.