Custom Palletizing Solutions with Industry-Leading Components

We build fully automated palletizing systems by integrating the best robotic arms, custom grippers, and adaptable automation platforms. Our solutions are tailored to your specific production needs, ensuring seamless integration and long-term reliability.

- Robotic Arms – Selected for optimal reach and payload capacity, ensuring the right fit for your operation.

- End-of-Arm Tooling – Custom-designed grippers and vacuum solutions for secure and precise material handling.

- Smart Palletizing Systems – Adaptable for varied product types, pallet configurations, and production demands.

Why Automate Your Palletizing Process?

- Increase Throughput & Efficiency – Speed up palletizing to meet higher production demands.

- Improve Worker Safety – Reduce repetitive strain injuries and create a safer work environment.

- Lower Labor Costs – Minimize reliance on manual labor and optimize resource allocation.

- Adapt to Market Demands – Scale operations quickly without major system overhauls.

- Minimize Downtime – Reduce disruptions caused by labor shortages or inconsistent manual handling.

- Ensure Consistent Palletizing Quality – Automated stacking eliminates errors and improves load stability.

Palletizing Components

Palletizing Deployment

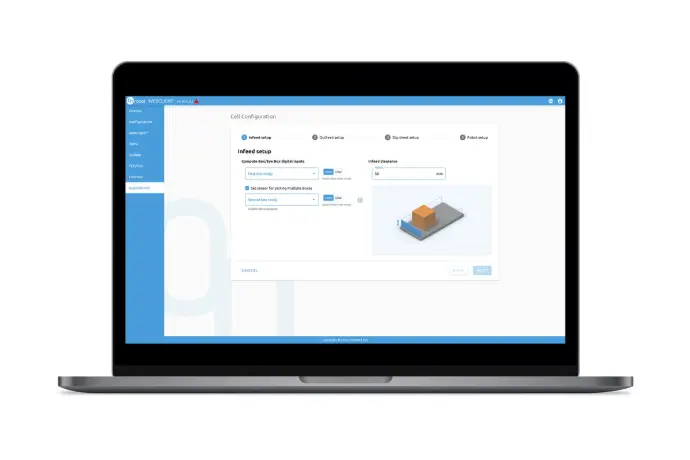

Deploy Your Palletizing System with No Coding Required

With D:PLOY technology, setting up a robotic palletizing system is easier than ever:

- No complex programming – Intuitive software reduces setup time by 80%.

- Adapt to new products fast – Easily update stacking patterns and product sizes.

- Seamless integration – Works with your existing automation infrastructure.

Palletizing Systems for Every Operation

We design automated palletizing solutions that fit a wide range of industries, ensuring efficiency, flexibility, and reliability at every stage of your end-of-line process.

Robotic Palletizing

Fully automated robotic palletizing solutions designed to handle products with speed and precision. These systems improve stacking accuracy, minimize labor dependency, and adapt to various product sizes and pallet configurations.

Conventional Palletizing

High-speed palletizing solutions for industries requiring consistent throughput and reliable stacking. These systems work seamlessly with existing production lines to maximize uptime and ensure stable, uniform loads.

Palletizing with Custom Grippers

End-of-arm tooling customized to your product type, ensuring secure and precise handling. Our vacuum, mechanical, and hybrid grippers accommodate everything from lightweight cartons to heavy, irregularly shaped loads.

Modular & Reconfigurable Systems

Designed for scalability and adaptability, our modular palletizing solutions adjust to evolving production needs, making them ideal for businesses requiring high-mix, low-volume flexibility.