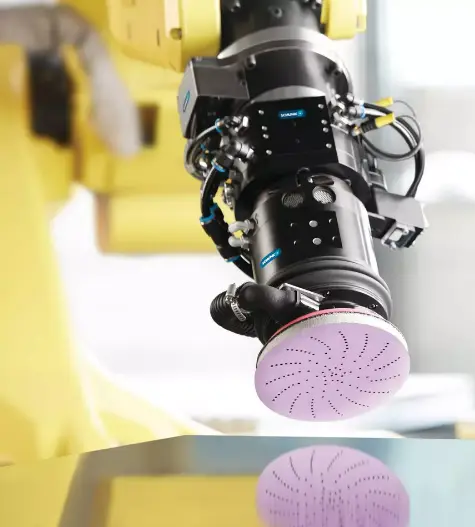

Our Approach to Material Removal Automation

We simplify robotic material removal by creating systems that fit your unique needs. By integrating robotic arms, tools, and software, we ensure smooth operation and reliable results.

Every solution is tailored to your process. We adjust tools, cutting settings, and techniques based on the material and workpiece details. This means greater accuracy, faster production, and less waste—helping you achieve better outcomes with less effort.

Benefits of Automating Your Material Removal Process

Streamlined Process

Eliminate ergonomic strain on employees performing dull, repetitive operations with hand tools

Employee Safety

Mitigate employee health risks from particle emissions (e.g. abrasive dust or chips)

Quality Control

More consistent quality of the workpiece final product, time and time again.

Increased Throughput

Reduction of workpiece processing time and increasing machining capacity

Material Removal Testing

Partnering with leading manufacturers like Schunk, our team of engineers are able to test your material removal application completely free of charge. Having a partnership with Schunk allows our team and our customers to gain access to an automation lab where we can put any application to the test. Through this process, we are able to deliver a clear line of site into what your automated process would look like in regards to feasibility, cycle time, tooling needs, and return on investment.

Contact our team to get started!

Material Removal Applications

Grinding & Sanding

Removal of coarser material or to prepare surfaces for downstream surface finishing

Deburring

Removal of burrs and chamfering of sharp edges after the actual workpiece machining is complete

Polishing & Finishing

Process to give workpiece a desired finish

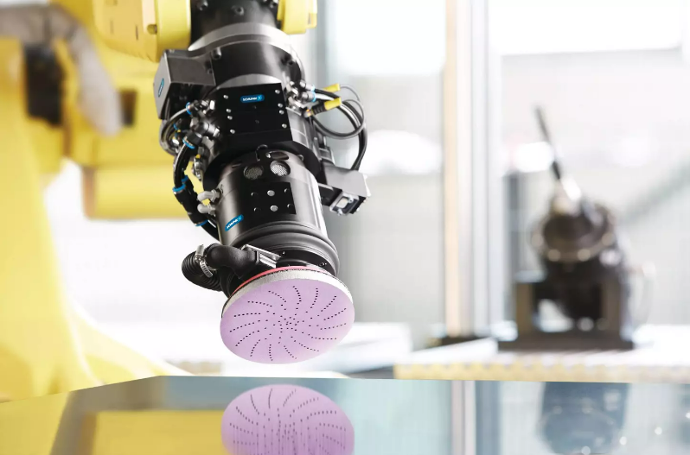

Product Spotlight:

Automated Sander Tool for Collaborative Robots

Complete electric random orbital sander for almost any automated surface finishing application, from sanding and buffing to polishing and cleaning. The Sander is available with everything you need to get started right away, and operates without external air supply, for no additional costs or complexity, and none of the dust or noise generated by traditional air sanders.