Why Automation Your Machine Tending?

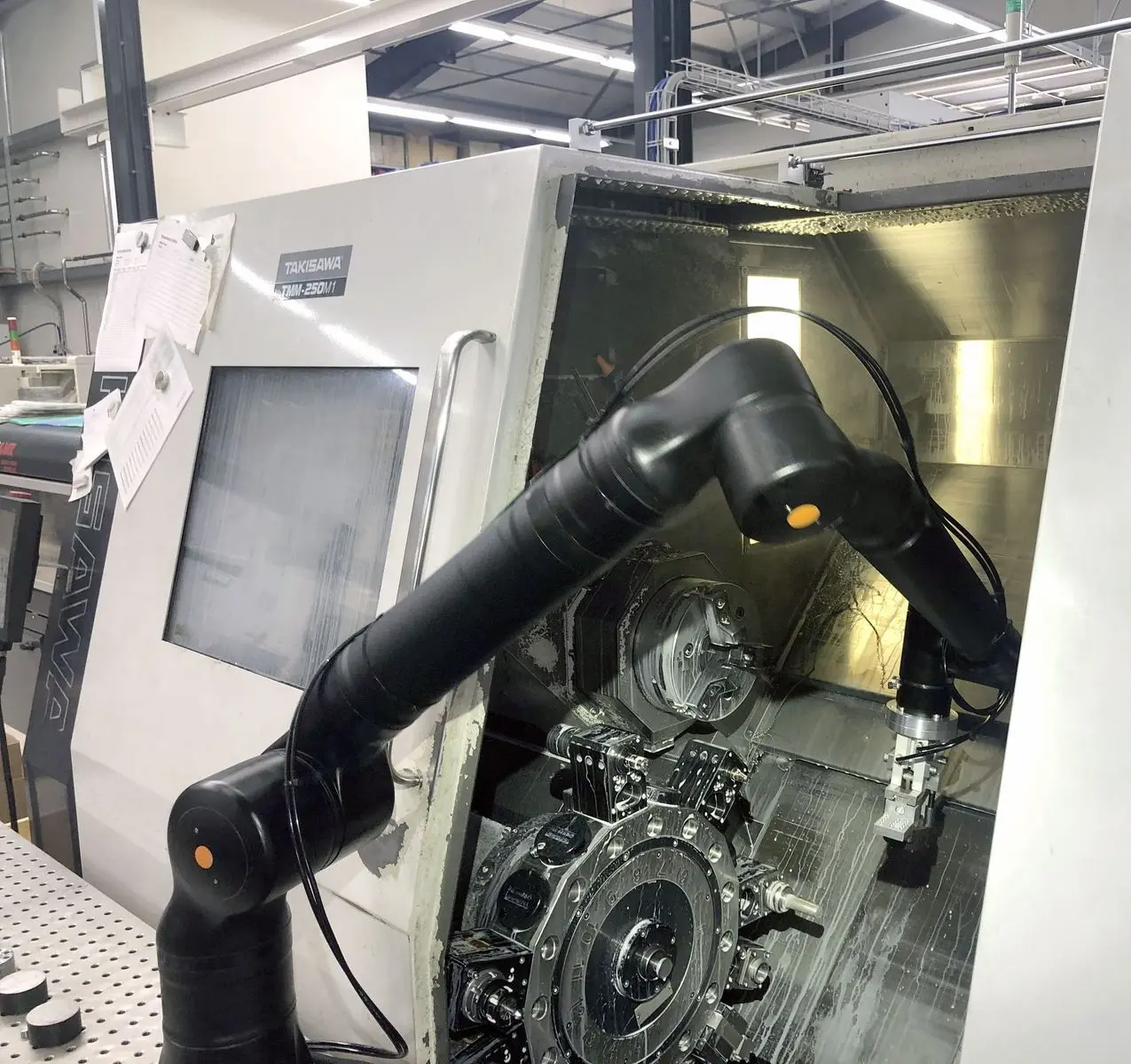

Machine tending is one of the most widely adopted automation applications. It involves automating the loading and unloading of machines, such as CNC lathes and milling machines.

As the availability of skilled labor declines, more companies are adopting automation to manage these tasks. Automated machine tending ensures continuous operation and increases efficiency.

By automating machine tending, businesses can reduce cycle times and enable around-the-clock production, making it a critical solution in industries like injection molding and CNC machining where uptime and precision are essential.

The Advantage of Working With Our Team

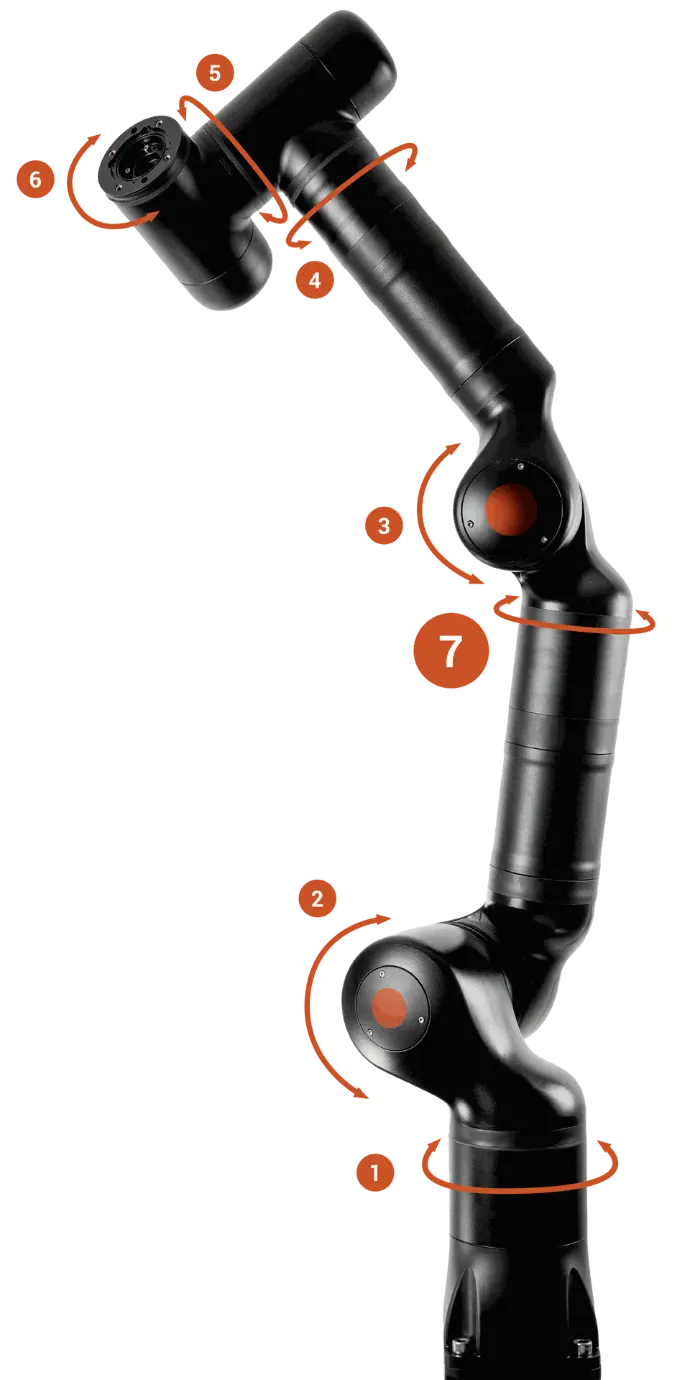

Wide Range of Robot Arms

Our robotic arms, sourced from top manufacturers, handle a variety of machine tending tasks with the precision and flexibility needed to meet modern industry demands

Custom Gripper Technology

We provide standard and custom gripper technology, tailored to your process, with the ability to create specialized solutions for niche applications.

Code-Free Automation

'DPLOY' is a zero-code platform that simplifies machine tending automation. It eliminates programming, allowing fast deployment on the manufacturing floor and speeding up operations.

Customized Solutions

We customize solutions to fit your specific workflows, ensuring seamless integration into your existing processes to boost efficiency and productivity.

Benefits of Automating Your Machine Tending Process

Increased Machining Efficiency

Automation in machine tending significantly speeds up production processes, allowing for more tasks to be completed in less time. This efficiency boost reduces cycle times and increases throughput, directly enhancing overall productivity.

Scalability and Flexibility

Automation solutions offer the flexibility to scale up or down based on production demands. This adaptability is key for businesses looking to expand or adjust their operations without major overhauls.

Enhanced Worker Safety

By automating repetitive and potentially hazardous tasks, businesses significantly reduce the risk of workplace injuries. This not only improves the safety environment but also reduces related costs such as compensation and downtime.

Reduced Operational Costs

Automating machine tending processes lowers labor costs and minimizes the expenses associated with manual errors and rework. Over time, these savings contribute significantly to reducing overall operational costs.

Labor Efficiency

In times of skilled labor shortages, automation ensures that production lines keep running. It allows businesses to allocate their human resources to more critical, less monotonous tasks.

Minimized Downtime

Automated machine tending is less prone to the interruptions that affect manual processes, resulting in minimized downtime. Continuous and reliable operation is critical for meeting production deadlines and maintaining workflow efficiency.

Data-Driven Insights for Continuous Improvement

Automation systems generate valuable data that can be analyzed for insights into process improvements, efficiency enhancements, and predictive maintenance, leading to smarter, data-driven decisions.

Consistent Quality and Precision

Automated systems deliver consistent results with high precision. This uniformity in operation reduces the margin of error, ensuring a consistent quality of output, which is crucial for manufacturing businesses.

Machine Tending Testing & Proof-of-Concepts

Free, Expert-Led Testing: Our engineers, in partnership with top manufacturers, provide free testing for your bin picking applications. This no-obligation service shows the real-world benefits of automation for your business.

Comprehensive Analysis, Custom Solutions: We offer detailed analysis on feasibility, cycle time, tooling, and ROI, delivering a custom solution that integrates smoothly with your operations.

Transparent, Informative Process: You'll receive a clear report on the impact of automation, empowering you to make informed decisions with no pressure.

Start Your Journey Easily: Contact our team to explore how automation can transform your business. We're here to support you every step of the way.