GRIP Handling Technology

Innovative Solutions for Automatic and Manual Change Systems.

Learn MoreThe GRIP Connector

Establish connections swiftly, effortlessly, and intuitively: The GRIP Connector provides nearly limitless options for linking cobots and tools. Explore the benefits of the SHW and MGW connectors.

GRIP's connection systems serve as the essential interface between robots and tools. Their quick-change systems consistently meet the rigorous standards of top-quality robot technology.

GRIP Benefits

Increase Precision and Repeatability

Robots are capable of executing tasks with high precision and consistent quality, which is particularly crucial in fields like electronics assembly, welding, and precision manufacturing.

Cost Efficiency and Increased Productivity

In the long run, handling technology helps lower costs and boost productivity by reducing throughput times and maintaining consistently high product quality.

Automation of Handling Processes

Robots are utilized to automate manual handling tasks, enhancing the efficiency and speed of production and assembly processes while minimizing human errors.

Quality Control and Improved Occupational Safety

Certain robots are specifically designed for inspection and quality control tasks to ensure adherence to quality standards. Handling technology takes over dangerous, repetitive, or ergonomically challenging tasks, thereby lowering the risk of injury for human workers.

Areas of Application in Industrial Robotics

Automotive Manufacturing

In automotive manufacturing, robots perform various tasks, including welding, painting, assembly, and handling heavy components. Their ability to execute precise and repeatable movements is crucial for the mass production of vehicles

Logistics & Warehousing

Robots are employed to sort, pack, pick, and palletize goods, enhancing efficiency in warehouses and distribution centers.

Heavy Industry

In industries like steel and metal manufacturing, robots are employed for handling heavy materials, as well as performing welding, cutting, and assembly tasks.

Construction Industry

In construction, robots are also used for tasks like welding, cutting, fastening, and even 3D printing building structures.

Food & Beverage Industry

In the food and beverage industry, robots are utilized for sorting, packaging, palletizing, and labeling. These robots are often specially designed to meet strict hygiene standards.

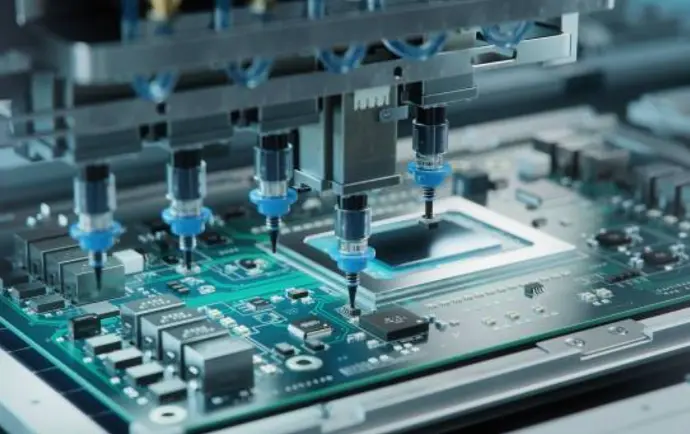

Electronics Manufacturing

In the electronics industry, robots are employed for precise and delicate tasks like placing components on circuit boards, soldering, testing, and packaging.

Pharmaceutical Industry

In the pharmaceutical industry, robots are employed for tasks like mixing chemicals, filling tablets, packaging, and labeling medicines, where precision and contamination prevention are essential.

Plastics & Metal Processing

In these industries, robots are utilized for tasks like injection molding, milling, drilling, cutting, and bending.

Healthcare & Medical Technology

Robots are utilized in medical device manufacturing, laboratory sample handling, and research to perform precise and repetitive tasks.

Recycling & Waste Management

Robots are employed to sort and handle recyclable materials and waste, enhancing efficiency and safeguarding human workers from hazardous substances.