1 µm

Resolution

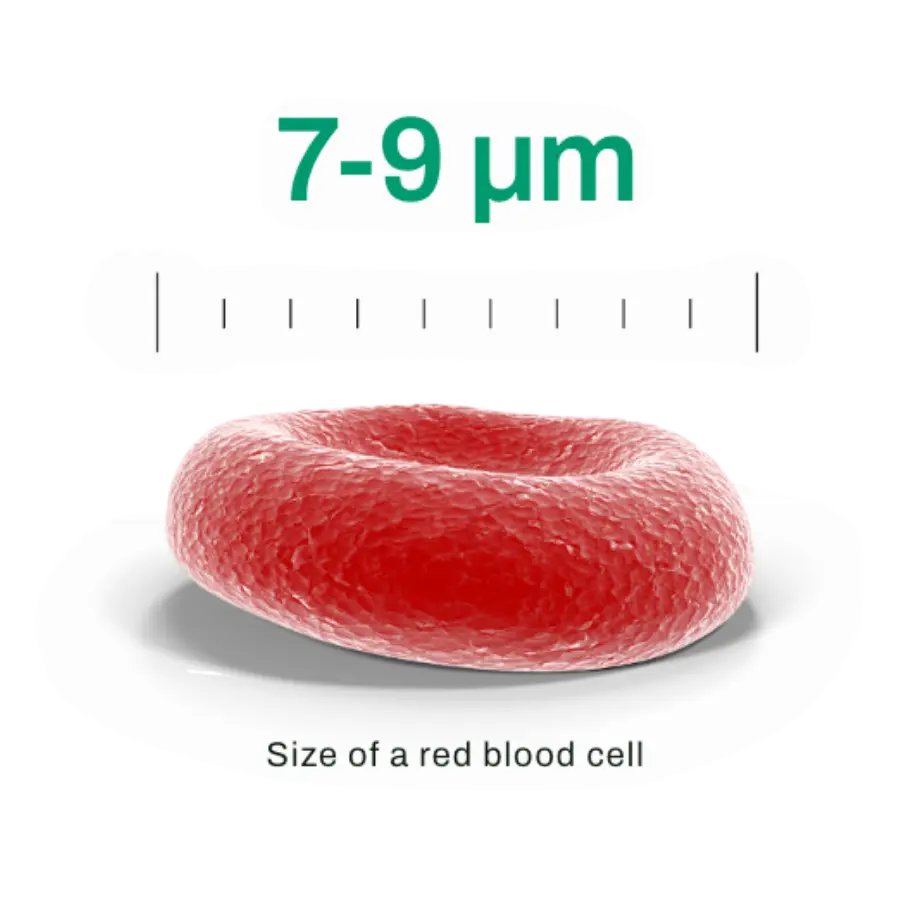

5 µm

Repeatability

1 kg*

Max. Payload

330 mm

Reach

Key Features of the Meca500

Highly Precise

0.005 mm position repeatability

Ultra-Compact

The controller is embedded into the base

Easy to Integrate

Hardware- and software-agnostic

Low TCO

Maximize value with minimal ownership costs

Energy Efficient

Consumes less than 100 W

Robust Build

Precision machined aluminum

The world's most precise six-axis industrial robot

Compatibility

Seamless Software Integration

Communication Protocols

EtherCAT

EtherNet/IP

PROFINET

TCP Socket

Programing Languages

C++

C#

LabVIEW

Python

Available PLC Packages

Allen-Bradley

OMRON

SIEMENS

BECKHOFF

Minimize Footprint

The Meca500 is smaller than any industrial robot arm. Featuring an embedded controller, it is also unbelievably compact.

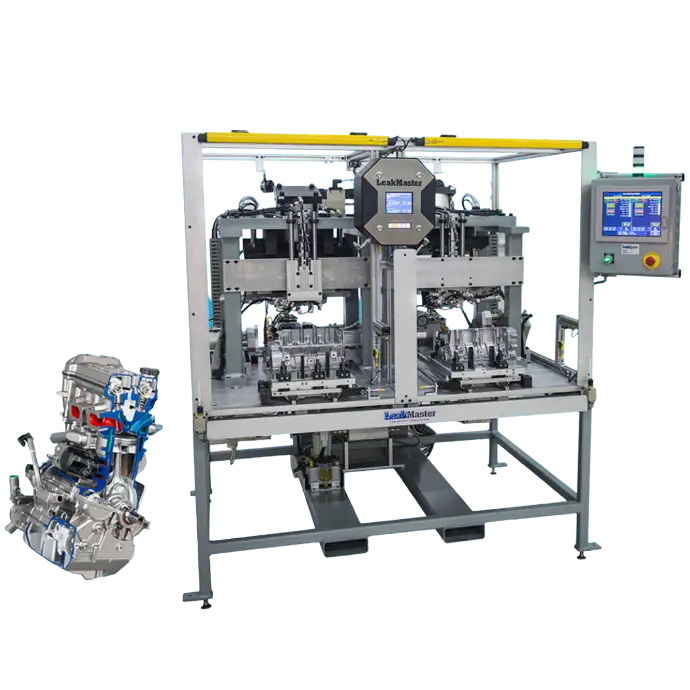

Reduce Tolerances

Built with precision-machined aluminum and zero-backlash gearboxes, the Meca500 is the world’s most precise six-axis robot. It boasts a repeatability of 5 μm

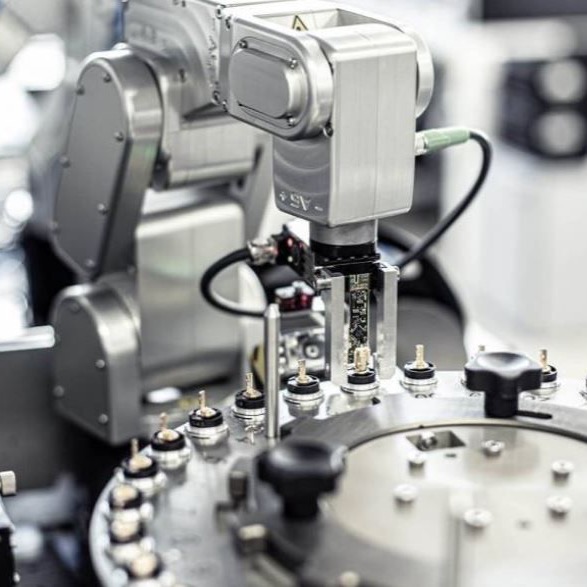

Facilitate Robot Arm Integration

The Meca500 is a plug‑and‑work automation component, easy to interface with any computer or PLC. Easily operate the robot using any programming language you prefer.

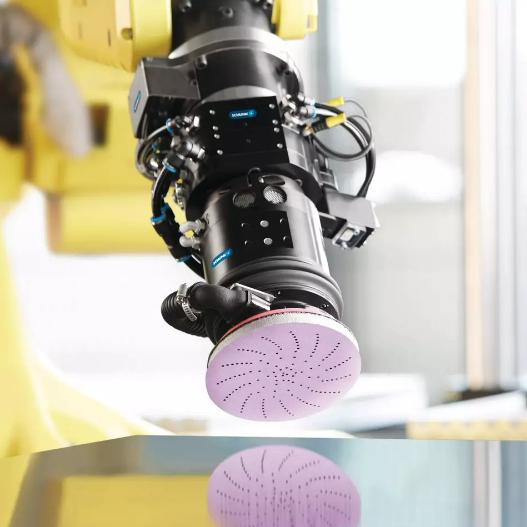

Benefit from Flexibility

The robot is easy to mount in any orientation. It automatically compensates for gravity, without requiring any software adjustments. This added flexibility enables easy integration in a wide variety of settings.

Technical Specifications

When fully extended, the length of the small industrial robot arm is about 330 mm.

Reach: 260 mm (see diagram below)

Payload: 0.5 kg rated (max. 1 kg)

Weight: 4.5 kg

Mounting: any orientation

Repeatability: 0.005mm

The Meca500’s controller is embedded in its palm-sized base. There is no bulky controller cabinet, no teach pendant, and no messy cables. With its tiny footprint, the Meca500 is ideal for small, confined spaces.

The Meca500 comes with an external 24V power supply that has an embedded safety module with an E-Stop and safety I/O interface. The power supply can be connected to any standard electrical outlet.

Supply voltage: 90-264VAC, 50-60 Hz, single phase

Safety module: Cat. 3 / PL d

Simply connect the robot to any computer or PLC via the Ethernet cable provided, and use a programming language of your choice (Java, C#, Python, etc.). The robot can also be controlled by most PLCs using either Ladder or Structured Text.

Users may communicate with the robot via EtherCAT, ensuring guaranteed response times. Alternatively, users may send Mecademic's proprietary commands to the robot arm (as parsed strings) over TCP/IP. The commands are typical robot instructions such as MoveLin(x,y,z,α,β,γ). Similarly, the robot's controller sends back strings with various types of feedback.

The robot’s controller features an intuitive web interface for operation. It can be accessed via any web browser.

Communication protocols: TCP/IP, EtherCAT, Ethernet/IP