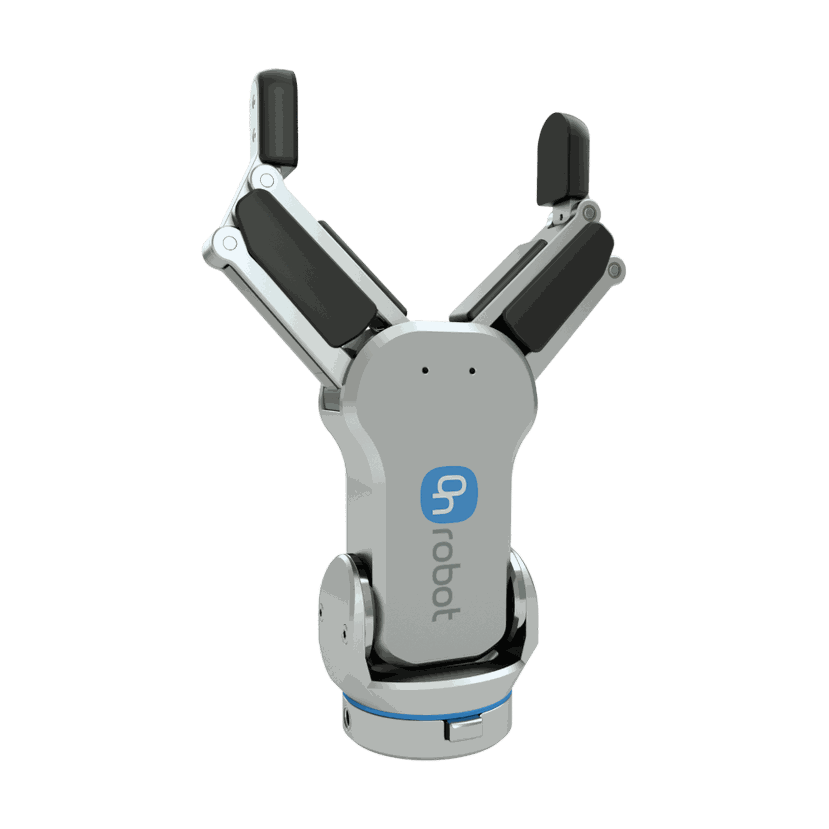

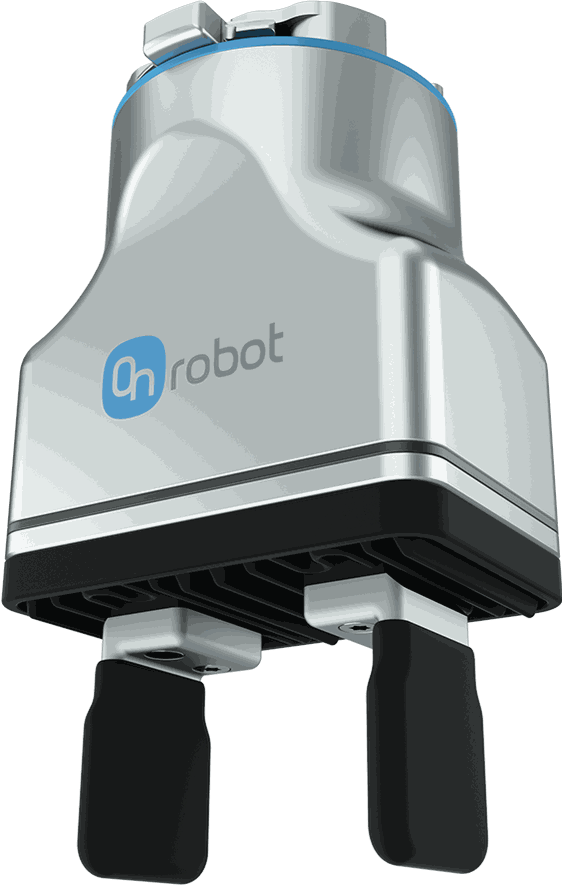

End-Of-Arm Tooling for All Applications

Collaborative and Industrial-grade gripping options

Contact usAll the tools you need at one place to automate more.

These solutions help small and mid-sized manufacturers optimize their processes and grow their businesses with greater flexibility, higher output and improved quality. Collaborative automation has levelled the playing field for small and mid-sized manufacturers, and as robots become easier to buy and implement, the tooling has become the vital element in adapting for a wide range of applications. Regardless of the robot brand, OnRobot provides compatibility and versatility beyond compare. It's everything manufacturers need from one supplier, providing even more value from the automation investment.

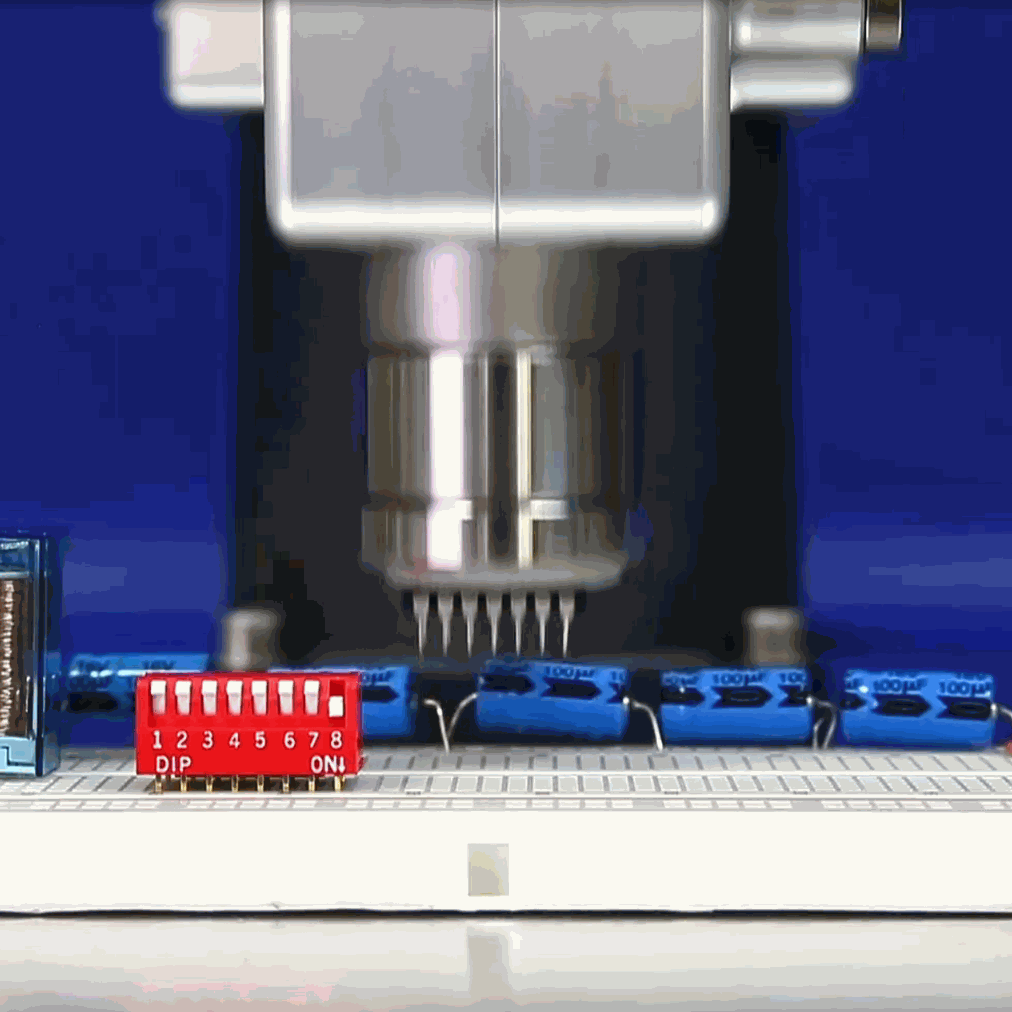

One-Stop-Shop for Collaborative Applications

All the tools you need at one place to automate more.

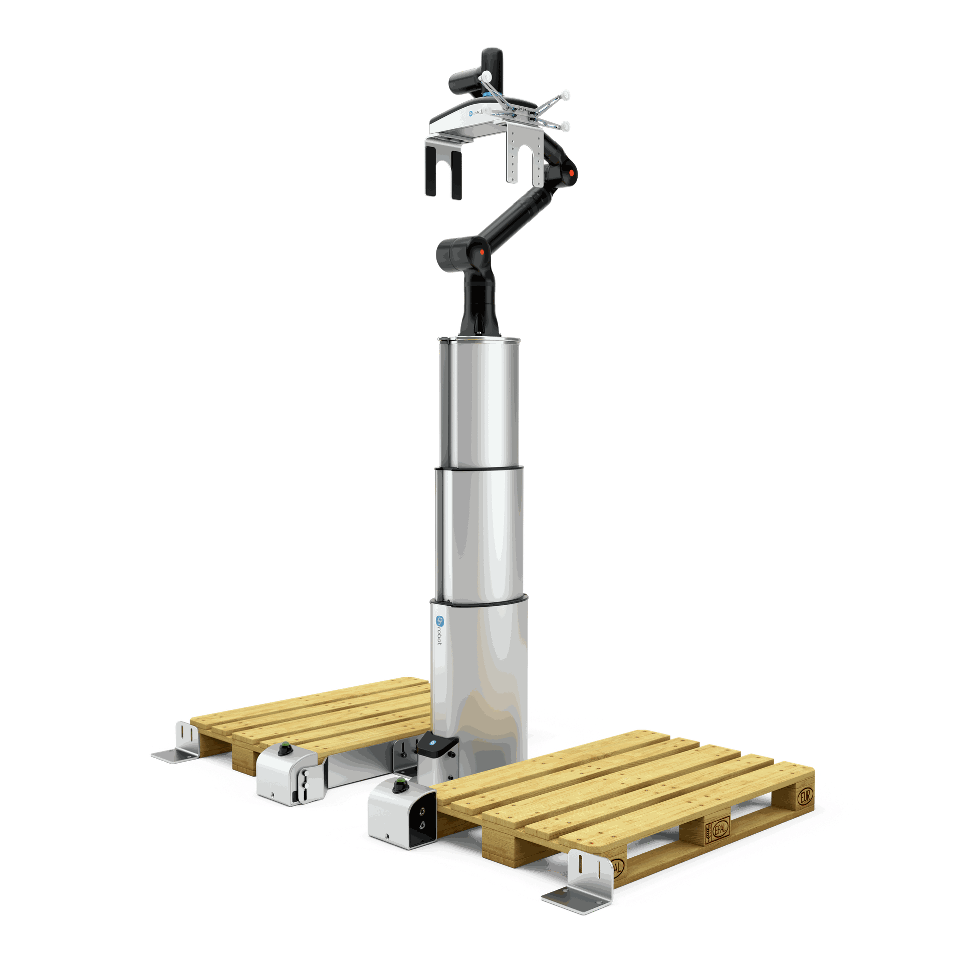

Multiple Tools, Robots, and Applications

Save cost and increase productivity with flexible automation tools.

One System,

Zero Complexity

Save time and grow your business fast with unified programming and easy deployment.