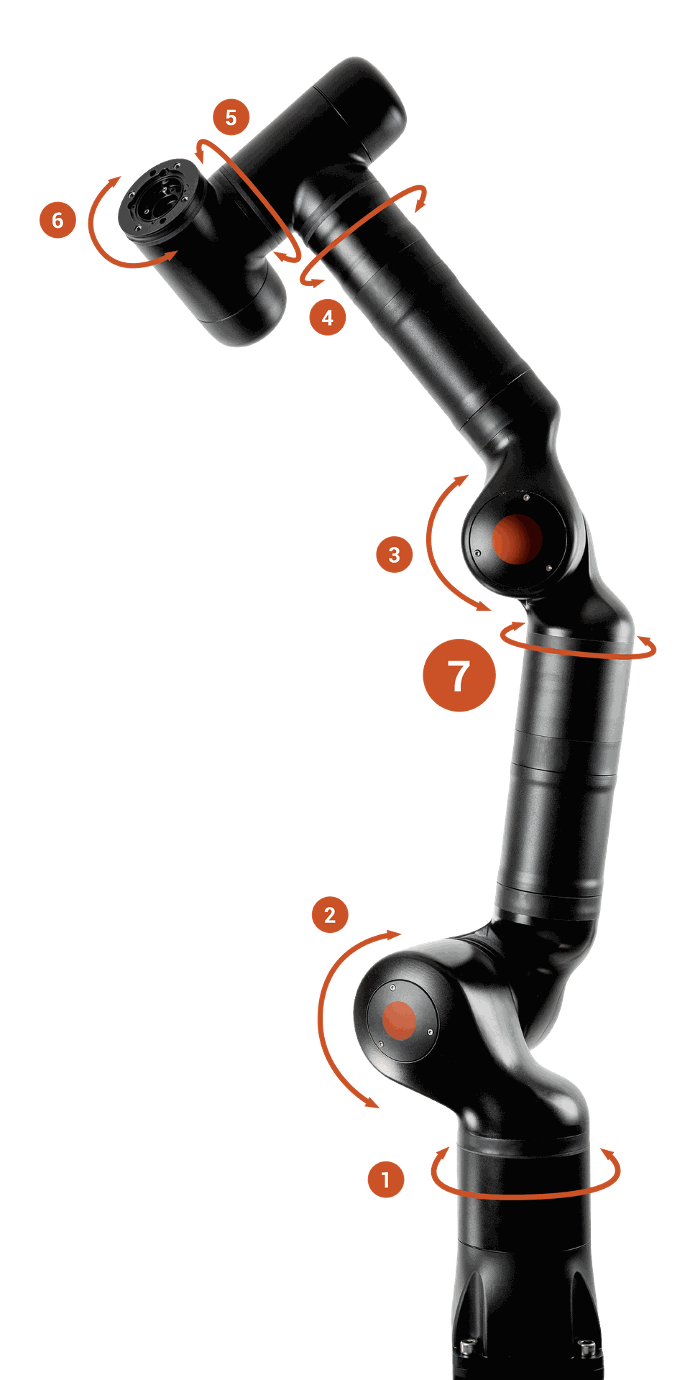

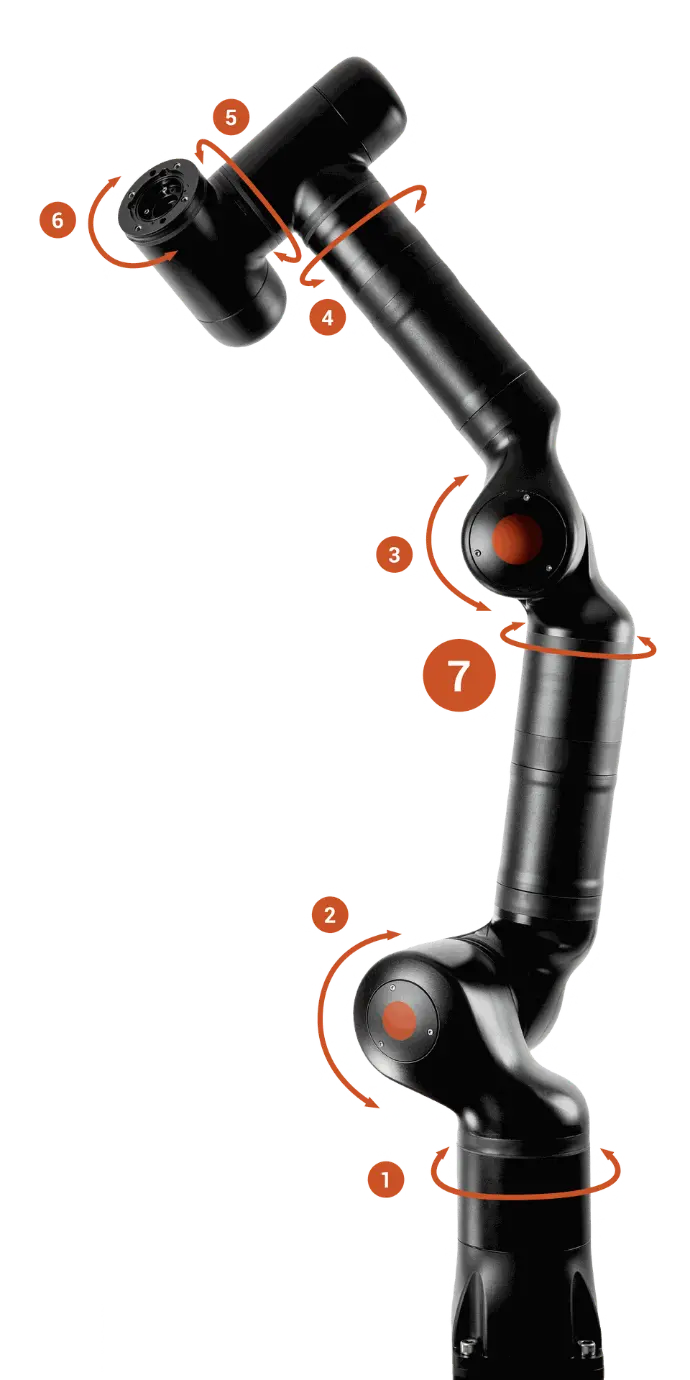

True to their claim “strong, fast, simple”, Kassow Robots develop and produce uniquely efficient industrial collaborative lightweight robots with 7 axes. Despite their large reach, Kassow Robots are extremely powerful, fast and suitable for use in small spaces. The technology is based on a novel design of both robot controller, user interface and arm mechanics. It has been developed by a team lead by Kristian Kassow, who, in his previous start-up years ago, was also responsible for other ground-breaking designs in the field of robotics.