This video showcases a machine tending solution our team developed for a client, integrating Kassow Robots' 7-axis cobot and OnRobot’s 2FG14 gripper. Designed for efficiency and precision, this system automates a dual-station process, ensuring continuous productivity with minimal operator intervention.

The Workflow in Action

Here’s how the system operates step by step:

Loading the First Station: The Kassow cobot picks up a raw workpiece and places it into the first FANUC Robodrill machine.

Seamless Processing: The cobot closes the machine door, initiating the processing of the part.

Dual-Station Efficiency: Once the first station completes, the cobot retrieves the finished part, transfers it to the second Robodrill, and loads a new raw part into the first station.

Final Output: Finished parts are deposited into a collection bin for the operator.

This continuous operation keeps both drill stations running at optimal capacity, reducing downtime and enhancing throughput.

Key System Components

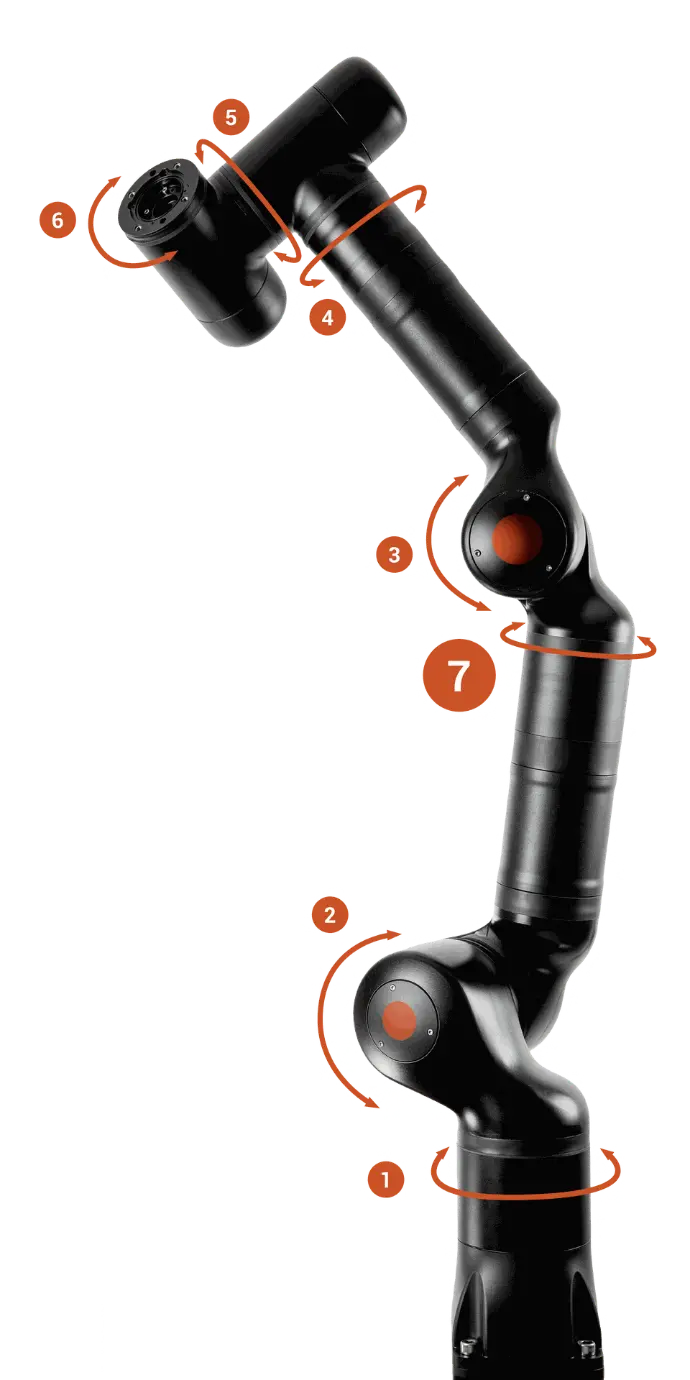

Kassow Robots 7-Axis Cobot

The 7th axis provides additional flexibility, enabling the cobot to maneuver in tight spaces and execute complex motion paths.

This design is particularly valuable when navigating between two closely spaced machines, ensuring precise positioning of workpieces.

OnRobot 2FG7 Gripper

Specifically designed for machine tending, the 2FG14 offers reliable and secure handling of workpieces.

Its high precision ensures accuracy throughout the process, minimizing errors and maximizing consistency.

Engineering Takeaways

Space Optimization: The additional axis of the Kassow cobot allows it to operate effectively in confined environments, reducing the need for reconfiguring workspace layouts.

Enhanced Productivity: Automating dual-station workflows ensures maximum uptime for both machines, significantly increasing overall efficiency.

Precision and Reliability: The combination of Kassow’s cobot and OnRobot’s gripper delivers a robust solution for handling intricate tasks with minimal oversight.