PreciseFlex 100 Cartesian Cobot

Payload: 3 kg

The PreciseFlex 100 is the only intrinsically collaborative cartesian robot available. It is ideal for many small parts handling applications delivering high speed and high reliability in a compact footprint.

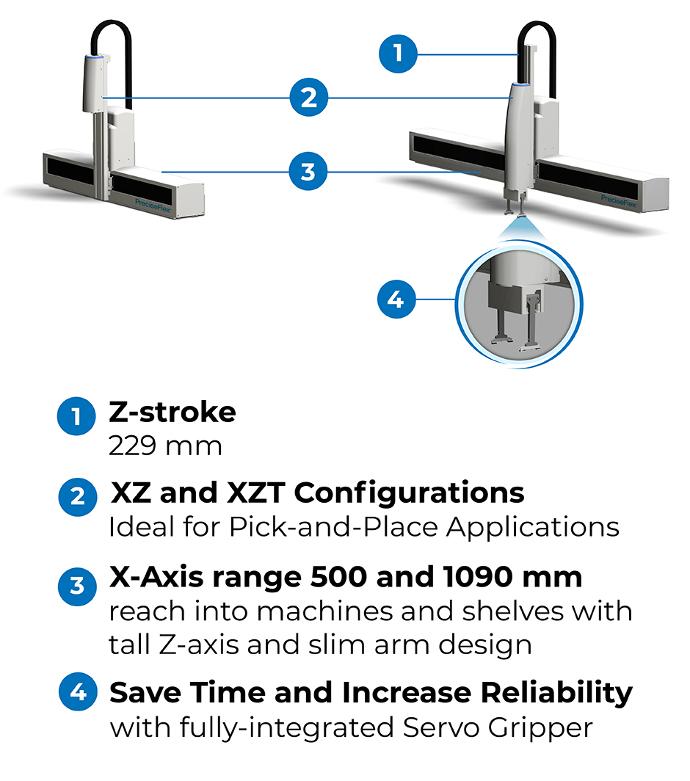

Available with 685mm and 1,270mm X-axis, and 230 mm Z-axis the PreciseFlex 100 is a bolt-on cobot that can be mounted over existing conveyors and other equipment.

Applications include Part Transfer / Pick & Place, and Small Parts Handling

With their space-saving footprint and highest workspace density, PreciseFlex robots make the most of your floor space. The controller is embedded in the robot, and there are no bulky robot cables to deal with.

Our optional servo grippers also make it easy to get started.

Features and Benefits

Cost and Space Saving Design

With the PP100, you only purchase the axes of motion that you need. And, it can be carried by one person, mounted on a table and, by plugging in just an AC power cord and an Ethernet cable, is ready to operate, which greatly reduces integration time and cost. The controller, power supplies and harnessing are embedded within the robot's structure, simplifying installations, reducing space, and allowing the PP100 to be mounted above existing work areas and equipment and "snapped" into place above conveyor belts. The collaborative Cartesian design allows for extremely small, cost saving workcells that have minimal impact on existing production. Unlike 6-axis articulated robots, there is no large dead space behind the robot and it can access the full rectangular XY region defined by the limits of travel of its axes.

Safe Mixed Manufacturing Environment

Collaborative robots potentially permit the creation of a mixed manufacturing environment where people can enter and efficiently work around robots without the loss of throughput. However, other "collaborative" robots must move slowly or use a reduced speed collaborative mode, impacting production whenever users are near. The PP100's unique combination of speed and safety allows its operation at full speed and delivers industrial throughput at safe ISO standard collaborative forces, so operators can move freely around the robot without concerns for their safety or loss of productivity

Simple to Program and Teach

The complex geometries of 6-axis collaborative robots make teaching positions difficult for operators, while the PP100's simple Cartesian geometry is particularly easy for new users to teach, since any position and move combination is intuitive and possible. In addition many collaborative robots use a programming environment with limited features to simplify setup for new users. Precise Automation's collaborative robots offer the flexibility of both an easy-to-use web based interface as well as an optional advanced programming environment as capable as any industrial robot. The easy-to-use Guidance Motion interface is accessible from any web enabled device and allows technicians or operators to quickly and easily setup and teach the PP100 to perform real work