Flexible automation is a concept that allows a production cell to be re-tasked quickly and easily. This gives the hardware applicability in multiple automation processes, while requiring minimal tooling changeover between tasks.

Traditionally, generalized automation implementation has been ruled out for many applications where a flexible cell would THRIVE due to the application requiring the handling of parts that are difficult to feed or pick, and/or running into applications with high mix / low volume attributes. However, given recent technological advancements, these applications that were once not feasible from a cost perspective are now much easier to invest in thanks to commercialized assets that are now re-deployable in facilities. With key components in a cell able to be re-deployed to other tasks when needed with minimal effort, risk and cost is reduced for the end-user.

Let's review some key components in a flexible automation cell: The contents are pretty simple, and boils down to four generalized components that allow the cell to receive, sense, and manipulate the desired object.

Flexible Automation Cell Components:

Part Feeders

The part feeder is a device that consistently presents the object(s) to the robot for handling or manipulation. They come in many forms and from many different manufacturers, but a general rule of thumb for a flexible cell is to select a feeder that can work with a mixture of parts, with minimal operator involvement. An excellent example of this would be the Asycube series from Asyril which fits 99% of part geometries and uses vibratory technology to ensure the part orientation - a very interesting concept for those who may be unfamiliar. You can see these feeders in action on a variety of parts on our page: Asyril Vibratory Part Feeders

Vision System and Sensors

We've almost all seen vision used in a manufacturing facility by now, whether it's strapped to the end of a robot or clamped to a conveyor to monitor parts as they flow down the line. In a flexible cell, the purpose of the vision will depend largely on the application. Generally speaking, it will collect data and either send coordinates to the robot for picking or inspect the parts against programmable criteria (geometric dimensions, presence/absence, etc).

Not all application require vision - simple pick and place tasks for example - where objects are in a predictable and consistent location every cycle.

The Robot

So far, we've covered the components that take the workpiece from detection to presentation. Now comes the critical act of actually moving the part - which is where the robot comes into play. Robots come in many different shapes and sizes: SCARA, 6-axis, collaborative, industrial, etc. The selection depends on the task at hand - and other variables like payload, reach, and cycle time requirements. When able, we like to lean towards the collaborative 7-axis robots from Kassow Robots. Collaborative robots, especially 7-axis ones, allow for easy repurposing which is what defines a flexible cell. Being collaborative in nature also allows for working alongside humans without guarding (usually).

End of Arm Tooling

Gripper selection is critical to successful implementation, because that is what will physically be handling the workpiece and ensuring it gets from point A to point B safely and accurately. Engineers will need to take into account factors such as payload, part delicacy, and environment of the application.

The end-effector technology offered to the market in the past few years has skyrocketed, and leading manufacturers like OnRobot offer grippers for most applications that you would find in your facility.

In summary, the key benefit of flexible automation is being able to re-deploy assets with minimal monetary and physical effort. Take a look back to the the year 2020, when COVID hit. Many businesses were able to find success by shifting their focus to manufacturing PPE and other relevant products that helped battle the pandemic, and having chosen the correct equipment was crucial. However, even less drastic shifts can prove flexible automation to be a business-savvy investment. With the labor shortage that we've been seeing, giving businesses the ability to quickly re-task their equipment to fulfill the duties of an absent worker have also been a proven pro to this type of investment.

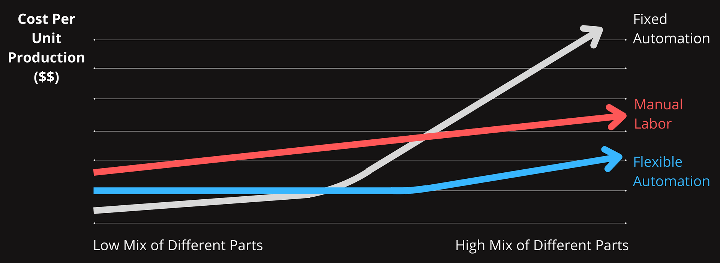

If you look at the graph below, you can see the value that a flexible solution brings when compared to traditional fixed automation or manual labor. If you look at the return on investment for a fixed solution, it only makes sense for when your facility manufactures the same part over and over again. Once your process dips to medium/high part mix, flexible automation becomes an extremely viable solution. With flexible automation, you can keep your costs reduced and have a much quicker return on investment while also preparing your company for any future pivots.

Improving Efficiency with Flexible Automation