Asyril’s Asycube flexible vibratory feeders provide efficient solutions for unbulking components of all types. Compatible with all robots and PLCs via TCP/IP and Modbus TCP, it integrates seamlessly with various plugins. The EYE+ smart control system optimizes Asycube performance for flexible feeding.

Its patented 3-axis vibration technology ensures fast, precise movement in all directions, eliminates edge buildup, minimizes recirculation, and handles delicate parts gently. This technology improves cycle times and efficiency, even on complex or perforated platforms.

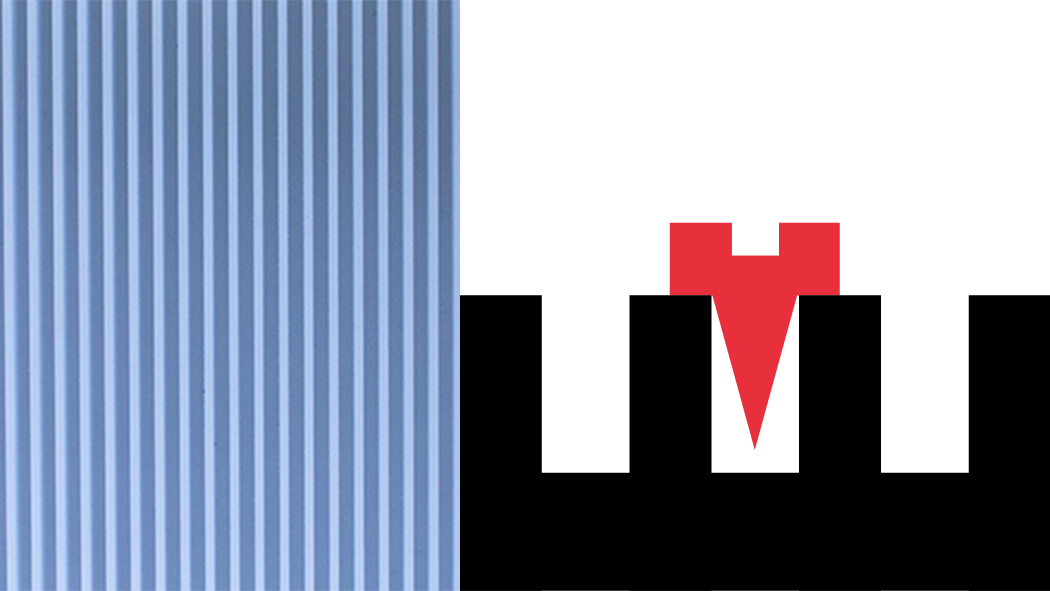

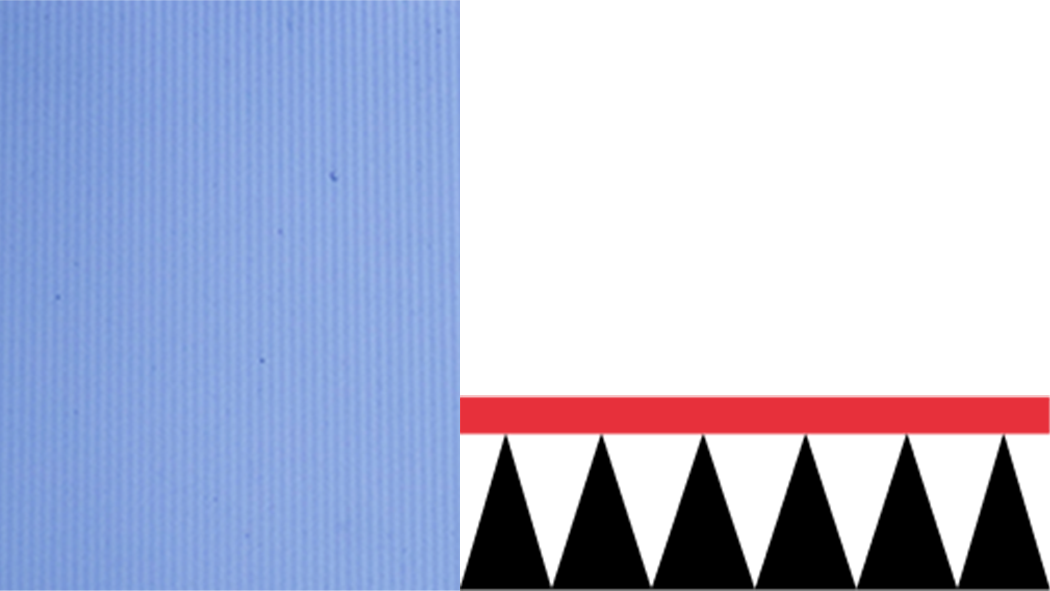

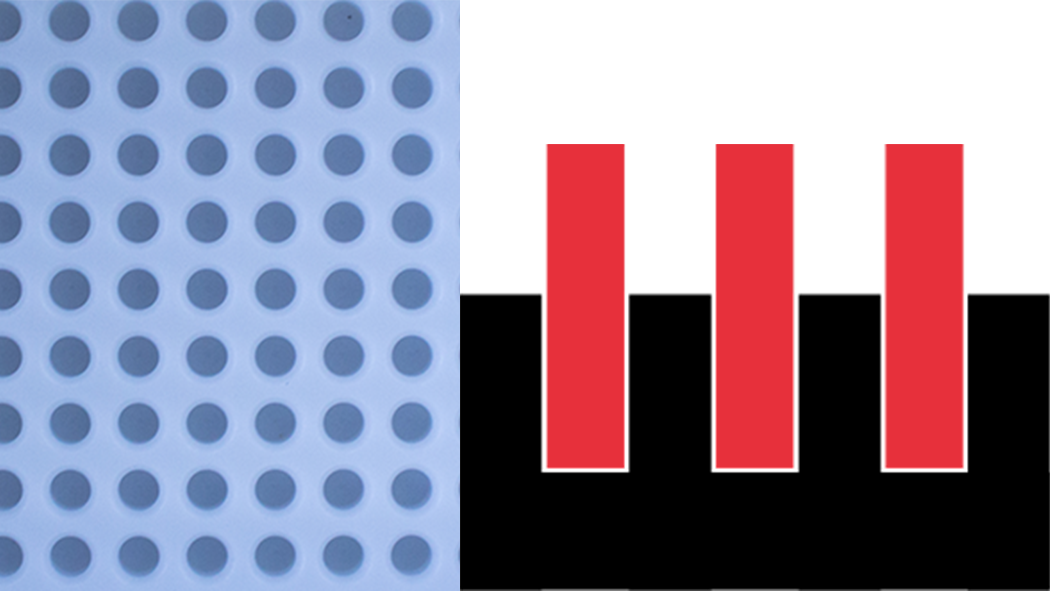

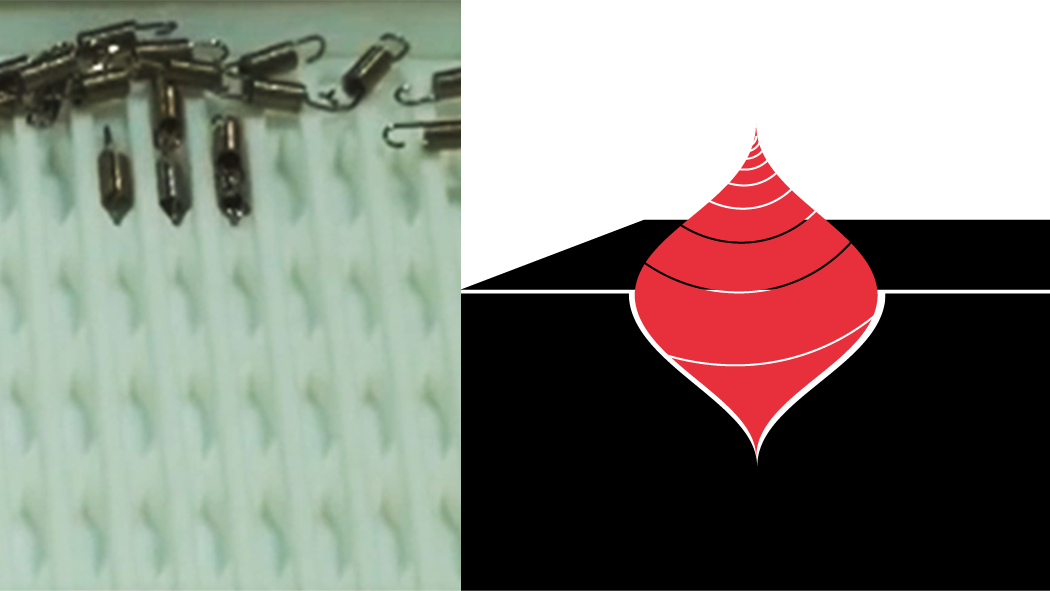

Customizable Platform Examples for All Part Configurations

Flat Platform

Deep Grooved Platform

Wide Grooved Platform

Micro-Structured Platform

Holed Platform

3D Pocketed Platform

Asycube Series

Each Asycube feeder is designed to be used with part sizes of various sizes. Take a look at the options below, and you will be able to get an idea of which feeder is right for you based on your application.

Keep in mind that these feeders work with nearly any part geometry, and if your robotic application demands the parts to be presented in a certain way then it is very easy to create a platform that ensures proper orientation.

Merlin Concept

Struggling to feed parts larger than 100 mm (4 in)?

Dealing with parts of varying shapes and sizes? Does your automation stop even when parts are still pickable?

Explore the new Merlin concept and eliminate leftover parts at the bottom of the bin.

Asyril’s Merlin concept elevates flexible feeding for large parts!

- Handle parts up to 300 mm (12 in)

- Teach parts from CAD files with an intuitive web interface

- Immune to different lighting conditions thanks to integrated lighting and AI-teaching

- Surround cameras detect pickable parts even during robot movement

- No complex robot joint moves or trajectories

- Constant cycle time through the very last part in the bin

- Compatible with heavy and vibration-sensitive parts

Integration Examples

Non contact handling of medical device, 3 way stopcock.

Robotics company uses flexible feeding for the assembly and handling of medical components.

Enhancing security and flexibility in medical device industry

Ward Automation uses cobots and Asycube feeders to offer their clients a safe and financially interesting assembly solution.

Placing copper spacers on electronic component

Many sectors require (electronic) power modules, especially for power plants and the manufacturing of locomotives and electric cars. In the production process of these power modules, copper spacers are used as thermal conductors to evacuate the heat of the electronic components.

Flexible Assembly Process using an Asycube 240 and a UR5 robot

The LIAA collaborative workcell by Asyril’s partner Teknologisk Institut (Denmark) demonstrates a collaborative and reconfigurable assembly process, where the Asycube 240 presents to the robot 4 different small elements to pick up, in order to assemble radial-axial bearings produced by the Slovakian company Spinea.

Precision Feeding and Assembly of Small Gear Wheels

The know-how of SMS Spinnler system building combined with Asyril’s high performance feeding components is a great fit for operations such as force fitting, flanging, crimping, riveting, marking, sorting and assembly of small parts.