Flexible Automation

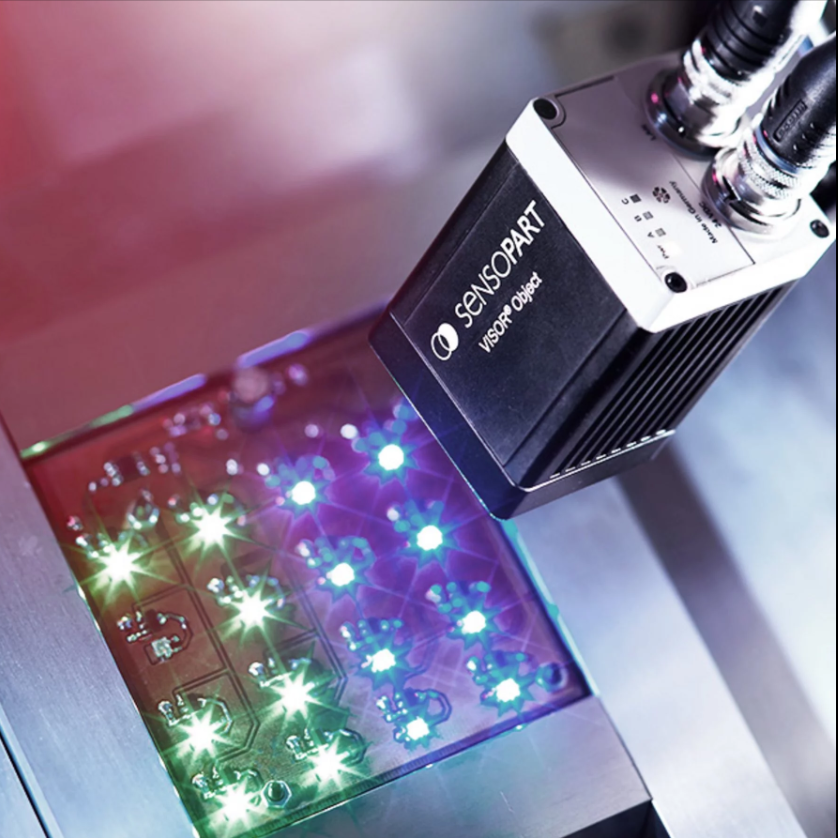

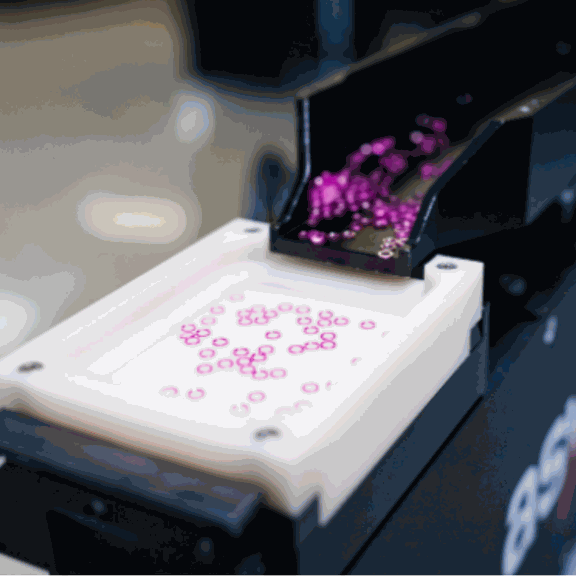

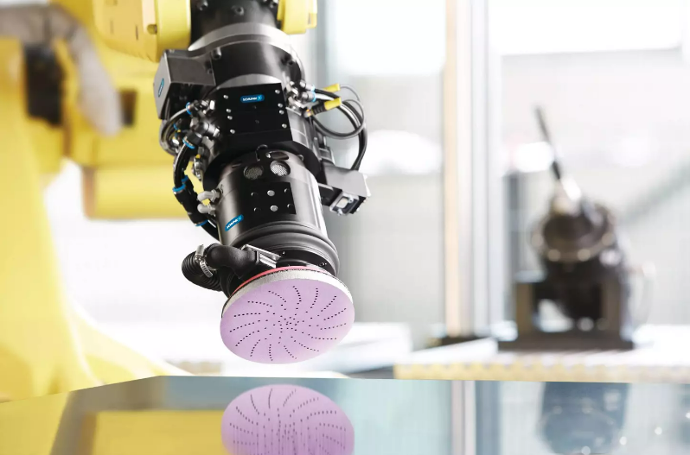

Solutions and components ranging from fully automated cells to specific automation components such as part feeders, grippers, vision systems, and more

Flexible Automation is one of the fastest growing areas of Factory Automation.

What is Flexible Automation? Flexible Automation is a concept that allows a robotic cell to be re-tasked quickly and easily allowing for multiple automation processes while requiring minimal change over. The main challenge has been dealing with parts that are difficult to feed and those with high mix / low volume. Traditionally, for many of these applications, automation has been cost prohibitive.

Investing in automation with redeployable assets now makes these applications feasible. Grouping key components together typically proves for a very fast return on investment. Risk is reduced as these components can be deployed to other automation tasks with minimal effort.

Benefits of Redeployable Assets

Return on Investment

Most cells can be deployed quickly, increasing the rate on ROI.

Redeployable Assets

Key components can be used in, and relocated to, other areas and applications when needed. This protects your investment and reduces bottlenecks and delays.

Multiple Processes

Use the same flex cell for multiple parts and or processes with minimal (if any) tooling changes.

Save on Labor Costs

We've all heard about the labor issues. Flexible Automation allows for re-allocation of human labor from dangerous, repetitive tasks.

Skyrocket Efficiency

Reduce costs of your operations and keep your business running smoothly.

Increase Product Quality

Flexible automation of processes allows for standardized product, and lets you maintain control on your business's products.